The beverage industry, celebrated for its vast array of drinks from zesty juices to craft beers, is a domain where precision, cleanliness, and efficiency are paramount. At the epicenter of this intricate process are the Construct pipelines, responsible for a flawless liquid transition. When discussing cutting-edge techniques and equipment associated with these pipelines, one name stands out - Swisstech Schreiner. Let's dive into the world of Constructing pipelines in the beverage sector, spotlighting the role of Swisstech Schreiner.

Understanding Construct Pipelines

Construct pipelines are the lifelines of the beverage production arena. They are engineered channels tailored to transport ingredients and beverages seamlessly, upholding the original taste, quality, and safety standards of the product.

Swisstech Schreiner: Pioneering Excellence

While the name Swisstech Schreiner might not be familiar to the average consumer, within the beverage and manufacturing industry, it symbolizes innovation and precision. Here's what makes Swisstech Schreiner pivotal in the realm of Construct pipelines in the beverage industry:

State-of-the-Art Technology: Swisstech Schreiner equips manufacturers with top-notch technology, ensuring that the pipelines function optimally, resulting in a consistent product batch after batch.

Hygienic Solutions: Beverages demand rigorous hygiene standards. Equipment from Swisstech Schreiner is designed to meet and often exceed international hygiene benchmarks, ensuring a safe and pure end product.

Durability and Reliability: With equipment and solutions tailored for the intense demands of the beverage industry, Swisstech Schreiner guarantees a longer lifespan for Constructing pipelines and reduced downtime, translating into increased profitability.

The Fusion of Construct Pipelines and Swisstech Schreiner

Quality Flow: Swisstech Schreiner's technological prowess ensures that the Construct pipelines are devoid of any flaws, leading to a uniform, obstruction-free flow. This is crucial in preserving the integrity of beverages.

Efficiency Boost: Leveraging advanced tools and systems from Swisstech Schreiner can augment the efficiency of the production line, streamlining processes and optimizing resource utilization.

Maintenance work and Upgrades: The dynamic nature of the beverage industry requires flexibility. With Swisstech Schreiner's solutions, pipelines can be effortlessly maintained, and potential upgrades can be integrated without disrupting the existing workflow.

The blend of construct pipelines with Swisstech Schreiner's expertise in the beverage industry continues to evolve. Swisstech Schreiner, dedicated to precision and innovation, will be instrumental in defining the future of beverage production.

=> Read more about Construct Pipelines in beverage industry at : Construction of pipeline systems in the beverage industry

Why Orbital welding machine Is the Best Welding Type for Pipeline Applications in the beverage industry

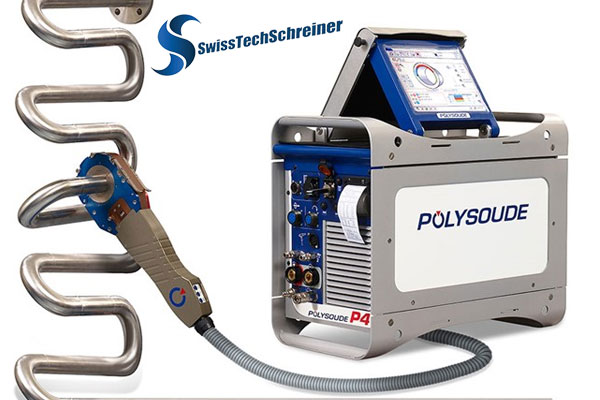

Constructing pipelines in the beverage industry is a critical aspect of ensuring the efficient and safe production, transportation, and distribution of various beverages. One advanced method that has gained significant popularity for welding pipelines is the use of orbital welding machines. These machines offer precise and high-quality welding, meeting the stringent standards required in the food and beverage sector.

Orbital welding machine is automated systems designed to perform circumferential welds around pipes with a high degree of accuracy. They consist of a welding head that rotates around the pipe's circumference while simultaneously feeding the welding electrode. This process ensures uniform and consistent welds, minimizing the risk of defects that could compromise the integrity of the pipeline.

Here's how the use of orbital welding machines benefits pipeline construction in the beverage industry:

Quality and Consistency: The beverage industry demands impeccable hygiene standards. Orbital welding machines provide consistent and repeatable weld quality, reducing the likelihood of defects, leaks, and contamination. This is crucial for maintaining the purity of the beverages being transported through the pipelines.

Precision: These machines are capable of accurately controlling parameters such as welding current, travel speed, and electrode feed rate. This precision results in strong, defect-free welds, ensuring the pipeline's longevity and minimizing the need for repairs or replacements.

Cleanliness and Hygiene: Stainless steel is a common material used in beverage pipelines due to its corrosion resistance and ease of cleaning. Orbital welding produces clean, smooth welds without spatter, reducing the risk of bacterial growth or buildup of residue inside the pipeline.

Reduced Downtime: With precise and efficient welding, pipeline construction can be completed more quickly. This minimizes production downtime and ensures a timely setup for beverage processing and distribution.

Operator Safety: Orbital welding machines are designed to be operated by skilled technicians who set up the parameters and oversee the process. This reduces the risk of human error and enhances operator safety by limiting their exposure to welding fumes and other hazards.

Documentation and Traceability: In industries with strict regulatory requirements like the beverage sector, maintaining accurate welding records is crucial. Orbital welding machines often come equipped with data logging capabilities, providing a record of welding parameters and ensuring traceability for quality control and compliance purposes.

Cost-Efficiency: While the initial investment in orbital welding equipment might be higher, the long-term benefits in terms of reduced maintenance, repairs, and downtime can lead to substantial cost savings.

Adaptability: Orbital welding machines can be used for a variety of pipe sizes and materials, making them suitable for different stages of beverage production and distribution.

=> Read more about Orbital welding machine at: (Orbital welding machine) Máy hàn quỹ đạo: giải pháp hiệu suất dành cho doanh nghiệp

In conclusion, constructing pipelines in the beverage industry using orbital welding machines offers numerous advantages in terms of quality, consistency, precision, hygiene, and efficiency. As technology continues to advance, these machines are likely to play an increasingly significant role in ensuring the smooth and safe operation of beverage production and distribution pipelines. Contact with Swisstech Schreiner to get the newest information and the solutions for business in this term.

Swisstech Schreiner.

Add: ch 4153 reinach and hcm city vietnam

Hotline: (+84) 931 - 386 - 062

Phone: (+84) 931 - 386 - 062 +84931386062 ( zalo / viber / whatsapp )

Email: swiss.tech.schreiner@gmail.com

Other News

Công nghệ hàn quỹ đạo cho đường ống kích thước lớn

Cùng Swisstech Schreiner khám phá công nghệ hàn quỹ đạo Orbital welding technology tiên tiến dành cho đường ống kích thước lớn, một giải pháp hiệu quả và đáng tin cậy để đảm bảo mối hàn chất lượng cao và độ bền vượt trội.

SwissTech Schreiner – Hàn Quỹ Đạo Tối Ưu Cho Ngành Nước Giải Khát

Trong các dây chuyền sản xuất nước giải khát, hệ thống ống dẫn đóng vai trò quan trọng trong việc vận chuyển nguyên liệu và sản phẩm. Việc sử dụng ống thép không gỉ vi sinh cùng công nghệ hàn quỹ đạo là lựa chọn tối ưu để đảm bảo

Nên Chọn Mua Hay Thuê Máy Hàn Quỹ Đạo Orbital

Máy hàn quỹ đạo Orbital (Orbital welding machine) - Công cụ không thể thiếu trong các ngành công nghiệp, tạo nên mối hàn nhất quán, chất lượng cao. Công nghệ hàn quỹ đạo phục vụ cho tất cả các ngành từ hàng không vũ trụ, ô tô, dược phẩm và thực phẩm,...

Maintenance Work: Bảo trì hệ thống ống inox hiệu quả

Hệ thống ống inox được ứng dụng rộng rãi trong công nghiệp, thực phẩm, dược phẩm và hóa chất nhờ khả năng chống ăn mòn và bền bỉ. Tuy nhiên, nếu không thực hiện bảo trì hệ thống (Maintenance Work) định kỳ, hệ thống có thể gặp tình trạng tắc nghẽn, rò rỉ hoặc giảm hiệu suất vận hành, ảnh hưởng trực tiếp đến dây chuyền sản xuất.

The Advantages and Applications of Orbital Welding Machines in the Manufacturing Industry

What exactly are these machines, and how do they stand out in the crowded field of manufacturing tools? Join Swisstech Schreiner to dive into the fascinating world of orbital welding machines, the automated marvels of the welding world.

Hàn đường ống có độ tinh khiết cao (Orbital welding technology)

Công nghệ hàn quỹ đạo (Orbital welding technology), được biết đến với độ chính xác và hiệu quả, đóng một vai trò quan trọng trong việc đạt được các mối hàn chắc chắn và đáng tin cậy trong nhiều ứng dụng khác nhau. Hãy cùng Swisstech Schreiner tìm hiểu về công nghệ này qua bài viết sau.