The processing of stainless steel pipes by an orbital welding machine is a semi-automated process, but what does that need? For those new to orbital welding technology, here we lay out the information about stainless steel pipe processing by an orbital welding machine in detail.

The stainless steel pipe processing by orbital welding machine

Stainless steel pipe processed for use in the beverage, semiconductor, and pharmaceutical industries must be handled and cleaned in accordance with design requirements and relevant standards. Welds and heat-affected zones of stainless steel pipes are performed and controlled according to the standard. Hygiene and safety during and after welding are required and tested to meet strict standards.

In manufacturing plants, industrial piping systems play an essential role in the production process. Industrial piping systems include: compressed air piping systems, steam piping systems, condensate piping systems, process water piping systems, ice water piping systems, chiller piping cooling tower pipeline systems, gas and nitrogen pipeline systems, etc.

With the production process of any machine system, it also needs the above pipeline system to operate. Therefore, businesses must have technical knowledge about industrial pipeline installation.

Aims to ensure the quality and efficiency of industrial piping systems. Method of calculating and installing pipes from the main stainless steel pipe processing branching down to each small pipe to ensure the technical and aesthetic requirements of the plant.

Therefore, the design and installation of industrial pipeline systems also play a very important role. Depending on the terrain and technical requirements given so that we have the optimal plan for the industrial pipeline system. The technological pipeline system is very necessary for the industrial production plants of different industries such as: petroleum, pharmaceutical, food processing, beverage, etc.

The technological pipeline for transporting and distributing steam, gas, and oil... is the main metal pipeline, such as cast steel pipe, stainless steel pipe, zinc-coated steel pipe,.... transporting the refrigerants to the supply stations, and the machinery and equipment used to operate it.

Industrial pipelines are subject to pressure and high temperature of the used mediums, such as water, oil, etc., so the calculation, design, and construction of technological pipelines are very important to ensure technical requirements, aesthetics, and safety in use.

Details of construction of stainless steel pipe processing connections in technological pipelines include flanges, elbows, numbness, bolts, washers, and other details used to connect pipes, change the direction or diameter of pipes, branch pipes, or seal the ends of pipes.

Technology pipeline accessories include: test equipment, opening and closing devices (valves), safety devices, brackets, mounting brackets, and insulation (if any).

Technical pipeline installation, pipe welding, and connection details must follow the welding process, ensuring technical quality. welds, aesthetics. For pipelines under the pressure of technological pipelines, only welders with certificates of pressure welding may conduct the welding of pipes or pressure-resistant parts of pipelines. Technological pipeline welders must be qualified to meet the welding process.

All technological pipeline systems must be tested after installation to meet the requirements in the design regulations, except for the pre-fabricated assemblies and the final finished welds of the system, which are not subject to actual test conditions. Swisstech Schreiner is always proud to be the leader in the field of stainless steel pipe processing with a team of experienced employees.

With the criteria of "quality, safety, and quick construction", Swisstech Schreiner is always the unit that brings satisfaction to customers. We offer solutions about the stainless steel pipe processing for pipeline systems and services related to maintenance work and orbital welding technology. Contact us to get more information.

Swisstech Schreiner.

Add: ch 4153 reinach and hcm city vietnam

Hotline: (+84) 931 - 386 - 062

Phone: (+84) 931 - 386 - 062 +84931386062 ( zalo / viber / whatsapp )

Email: swiss.tech.schreiner@gmail.com

Other News

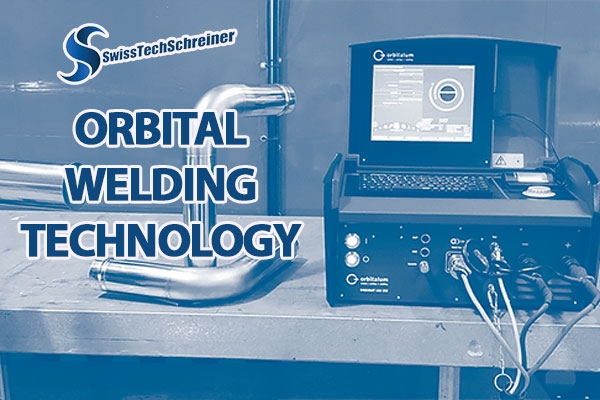

The orbital welding machine is the picture of the perfect weld.

While the cost of the equipment is somewhat high, orbital welding machine can provide 2-3 times higher productivity than traditional welding. People use orbital welding machine in aerospace, biotechnology, chemical , food and beverage industry, pharmaceutical, power, and shipbuilding industries.

Gia Công Ống Thép Không Gỉ: Giải Pháp Tối Ưu Cho Nhiều Ngành Công Nghiệp

Cùng Swisstech Schreiner khám phá các phương pháp hàn thép không gỉ và tiêu chí lựa chọn phù hợp cho dự án của bạn trong gia công ống thép không gỉ stainless steel pipe processing. Tìm hiểu sự đa dạng của các kỹ thuật hàn để đảm bảo chất lượng sản phẩm và hiệu quả sản xuất.

Precision and Durability Stainless Steel Pipe Processing

People often laud stainless steel for its strength, corrosion resistance, and aesthetic appeal. A significant facet of this material's utility lies in its transformation into pipes. Let's have Swisstech Schreiner delve into the world of stainless steel pipe processing.

Orbital Welding technology - automatic welding machine service

Do you need to rent, buy, train or modify an orbital welding machine or orbital welding technology services ? Contact our hotline: (+84) 931 - 386 - 062 or swiss.tech.schreiner@gmail.com for detailed information. Or you can fill out the form below to let Swisstech Schreiner know your request.

Quy trình bảo trì hàn (Maintenance work welding Process)

Trong quá trình sử dụng, các kết cấu hàn có thể bị hư hỏng hoặc xuống cấp do các yếu tố như thời tiết, tác động cơ học hoặc quá trình ăn mòn. Do đó, việc bảo trì hàn (Maintenance work welding) thường xuyên là rất cần thiết. Hãy cùng Swisstech Schreiner tìm hiểu quy trình bảo trì hàn qua bài viết sau.

Công Nghệ Hàn Quỹ Đạo Orbital Cho Ống Inox Vi Sinh Và Công Nghiệp

Công nghệ hàn quỹ đạo hay còn gọi là hàn orbital, đây là công nghệ hàn được sử dụng rộng rãi, mang lại các mối hàn nhất quán, chất lượng cao và thượng được các nhà thầu thi công đường ống vi sinh sử dụng.