Orbital welding technology is used in advanced projects because this technology is capable of producing welds to the specifications required by the most demanding industries. In such projects, there are no errors or flaws that can be accepted because they might lead to system failures or compromise experimental results.

The innovation of the welding technology

The first time that two pieces of iron were heated up and hammered until they came together is when welding was first invented. The first recognisable gas welding procedures were created in the late nineteenth century, and the art has since grown significantly. Arc welding rose to prominence in the 20th century and has been gradually improving ever since.

Today, high-quality welding machines now include innovative technology that embodies both advancements and ground-breaking innovations. Today's advancements in chemistry and metallurgy go hand in hand with automation and computerization. Due to this, welding operations may now meet demands for increased precision, enhanced weld hygiene, and increased welding output.

New technologies require cleaner and more precise welds in industries such as the food and beverage industry, pharmaceutical industry. That is the reason why orbital welding technology appears and has become more popular in the world.

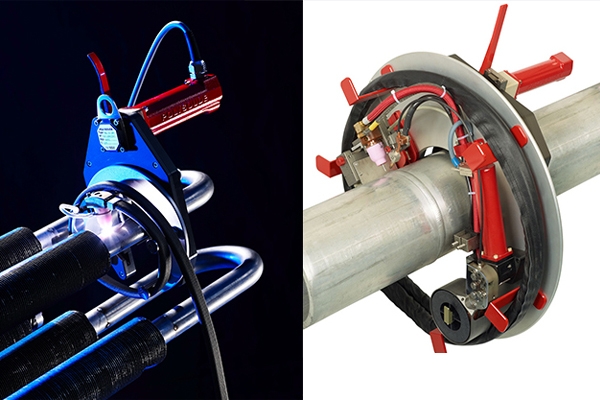

Orbital welding technology

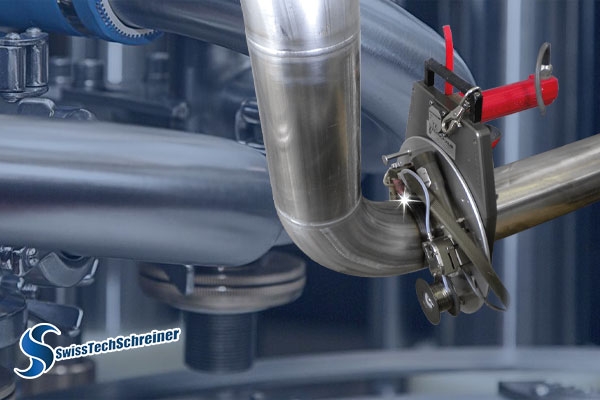

For connecting stainless steel pipes in industries which high-quality results are required, orbital welding tẹcnology is the method of choice.

The name of orbital welding technology comes from the circular motion a welding device makes around the workpiece.

Reasons to select Orbital Welding technology

Economic, technical, organizational, and other considerations may be more or less significant or may end up being the deciding factor in the decision to adopt automated or mechanized orbital welding technology. The orbital welding process has many advantages, making it suitable for industrial applications. The main benefits include.

Increased productivity compared to normal welding method

The automated or mechanized procedure results in enhanced productivity when compared to manual TIG welding. On-site complicated assembly jobs or repetitive work in the workshop, orbital welding technology equipment ensures that approved weld sequences are reliably repeated, hence time-consuming repair work will be reduced to a minimum.

Great weld quality that is constant

In general, mechanized equipment produces welds of higher quality than manual welding. The weld cycle can be repeated as often as required without variations and essentially without deviations and virtually without weld defects once a suitable weld program has been devised.

Operators' needed degrees of expertise

Welders with certifications are hard to come by and well paid. Nonetheless, professional technicians are able to use orbital welding equipment flawlessly and produce good results after receiving the necessary training. Using this device can cut down on personnel costs.

Environment

Even in extreme environmental circumstances, orbital welding technology can be executed . If the weld head is positioned correctly, it is possible to complete the weld from a safe distance even in situations with limited space or access, lack of visibility, presence of radiation. This is frequently assisted by a video transmission.

Authenticity - Quality Assurance

A modern orbital welding technology device is designed for real-time monitoring of the affecting weld parameters; a complete weld protocol can be generated and stored or printed out. If sophisticated data gathering devices are directly connected to a high-quality management system, automatic data transmission occurs without interfering with the welding process

Industries which apply the Orbital Welding Technology

- Food and beverage industry

- Pharmaceutical and Biotechnology industry

- Manufacture of Semiconductor devices

- Chemical industry,....

Safety considerations when using a orbital welding machine

Pipe Welding in industries requires the use of specialized tools, such as a orbital welding machine or orbital cutting machine and involves many safety considerations. When using an orbital welding machine , it is important to wear protective eyewear and PPE (Personal protective equipment) . Also, consider using appropriate shielding gasses for the welding machine.

The workpiece must be grounded before any welding operation can start. By taking these safety measures, you can ensure that the welding process goes smoothly and nobody is injured.

With many years of experience in the field of providing equipment such as orbital welding technology and stainless steel pipe processing and solutions for factories in the beverage industry, pharmaceutical factories, ... Swisstech Schreiner is confident to be a major contractor in Vietnam and the South Asia / Asia region.

Thanks to the investment in facilities, techniques and new technologies based on a set of international standards. In addition, the staff at Swisstech Schreiner are experienced and regularly receive intensive training to improve their skills.

With many years of operation in the field of mechanical engineering, we have designed, manufactured and supplied industrial products with high quality for large and small projects throughout Asia in general and Vietnam in particular. Swisstech Schreiner promises to bring customers top products and services.

Swisstech Schreiner.

Add: ch 4153 reinach and hcm city vietnam

Hotline: (+84) 931 - 386 - 062

Phone: (+84) 931 - 386 - 062 +84931386062 ( zalo / viber / whatsapp )

Email: swiss.tech.schreiner@gmail.com

Other News

Cấu tạo của máy hàn quỹ đạo (orbital welding machine) và cách hoạt động

Máy hàn quỹ đạo (orbital welding machine) là gì? Cấu tạo và cách thức hoạt động của máy là như thể nào? Hãy cùng Swisstech Schreiner tìm hiểu chi tiết về máy hàn quỹ đạo (orbital welding machine) ở bài viết dưới đây nhé.

Beverage industry - Giải pháp tối ưu cho ngành công nghiệp nước giải khát

Công nghệ hàn quỹ đạo là bước tiến quan trọng giúp ngành công nghiệp nước giải khát nâng cao chất lượng sản phẩm và tối ưu hóa quy trình sản xuất. Việc đầu tư vào công nghệ này không chỉ giúp các doanh nghiệp đáp ứng các tiêu chuẩn quốc tế mà còn tạo lợi thế cạnh tranh bền vững trên thị trường.

Sử dụng máy hàn quỹ đạo Orbital welding machine

Hàn quỹ đạo là công nghệ hàn tự động tiên tiến, giúp tạo mối hàn chính xác, đồng nhất và sạch sẽ, phù hợp cho các ngành như dược phẩm, thực phẩm, và hàng không. Tìm hiểu về lợi ích, ứng dụng và cách thức hoạt động của hệ thống hàn quỹ đạo trong bài viết này.

Nguyên nhân vật liệu lại quan trọng khi gia công ống thép không gỉ

Cùng Swisstech Schreiner khám phá lý do tại sao việc lựa chọn vật liệu lại quan trọng khi gia công ống thép không gỉ Stainless steel pipe processing. Tìm hiểu các yếu tố ảnh hưởng đến chất lượng và độ bền của sản phẩm để đảm bảo hiệu quả cao nhất trong quá trình gia công.

Công Nghệ Hàn Tự Động Ống Thép (Orbital Welding Technology)

Hàn quỹ đạo là phương pháp tự động giúp loại bỏ tối đa các lỗi do con người gây ra trong quá trình hàn thủ công. Nhờ đó, sản phẩm cuối cùng không chỉ có chất lượng mối hàn đồng đều mà còn rút ngắn thời gian sản xuất đáng kể.

Bảo trì trong ngành nước giải khát (Beverage industry)

Bảo trì là một hoạt động không thể thiếu trong ngành nước giải khát, vì nó ảnh hưởng trực tiếp đến chất lượng và an toàn của các sản phẩm dành cho người tiêu dùng. Tuy nhiên, việc bảo trì cũng gặp phải nhiều khó khăn và thách thức do các yêu cầu quy định nghiêm ngặt, các thiết bị sản xuất phức tạp. Trong bài viết này Swisstech Schreiner sẽ chia sẻ tầm quan trọng trong công việc bảo trì (Maintenance work) và quy trình bảo trì cho ngành nước giải khát (Beverage industry) hiệu quả nhất nhé.