Orbital welding machine are becoming more and more popular. People are aware of the advantages of this welding kind, and this machine applications are expanding. This article will tell you more about orbital welding machines and applications.

High-quality welds are produced by orbital welding machine

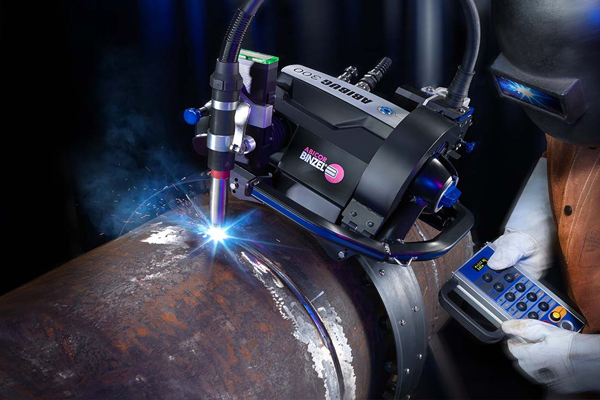

In an advanced form of welding known as orbital welding, the arc is continuously mechanically turned 360 degrees around a stationary workpiece. To solve the problems of operator error in manual gas tungsten arc welding (GTAW) procedures, this process was created.

In an orbital welding machine, a process runs under computer control with very little intervention from the operator. This process is specifically used for repeatable welding and high-quality welding.

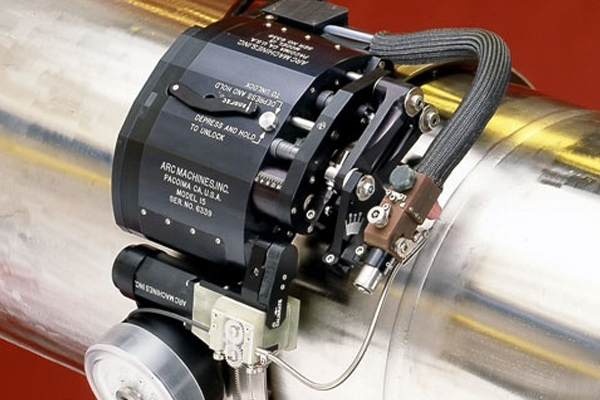

The controller, the power supply, the welding head, and a wire feeding mechanism are the primary parts of each orbital welding machine. There are a number of aspects of orbital welding equipment that can affect the quality of the weld.

The size, arc length, and pulse frequency of the welding current, as well as welding speed, thermal conductivity, weld preparation, inert shielding gas, filler material, and parent material, are some of these factors. The ability to accurately adjust these parameters for each welding activity is ultimately what results in a great weld.

The safety and quality standards in manual welding are challenging to attain.

This is a result of specific welding positions, where limited access frequently results in poor welds. At each torch location, surface tension and gravity forces must be perfectly balanced in order to have total control over the weld pool. Some steps of the orbital welding process are handled by mechanical components when using mechanized variations of the technology. Be aware that the process is always under the direction and supervision of a welder. Ideally, all welding settings are preprogrammed before the process begins.

Application of orbital welding machine

Steels, nickel alloys, copper, aluminum, titanium, and related alloys are just a few of the metals that can be welded. When used in an inert environment, this approach produces exceptionally clean, devoid of undesired spatter, low-particle outcomes.

The production of clean-room components for the semiconductor industry uses orbital welding machine because of its capacity to produce products of extremely high purity. The fabrication of machinery and pipes for numerous industries, including aerospace, shipbuilding, biotechnology, food and beverage industry, automotive engineering, orbital pharmaceutical, and chemical engineering, has now expanded to include this application.

Pores, notches, and inclusions in the weld seams must be completely avoided as they create weak spots that can eventually form cracks. This, in turn, can have serious consequences when it comes to component failure.

With a variety of procedures, orbital welding can produce welding that is dependable and reproducible in quality. Even with unique materials, tiny tube diameters, thick walls, and challenging working conditions, this can be completed to a high standard.

Although more expensive than standard welding equipment, conventional TIG offers much higher productivity. For more information on orbital welding applications, get in touch with a licensed welding business.

Swisstech Schreiner is the leading unit specializing in providing equipment and solutions for the installation of factories and workshops for industries in the fields of beverage industry , orbital pharmaceutical, chemical,... Equipment such as orbital welding machine , high-quality stainless steel pipe processing equipment, etc. was imported directly from Europe.

Contact us today for a consultation.

Swisstech Schreiner.

Add: ch 4153 reinach and hcm city vietnam

Hotline: (+84) 931 - 386 - 062

Phone: (+84) 931 - 386 - 062 +84931386062 ( zalo / viber / whatsapp )

Email: swiss.tech.schreiner@gmail.com

Other News

Different Techniques In Orbital Welding Technology

Orbital welding technology stands at the forefront of precision and efficiency in the welding industry. Join Swisstech Schreiner uncovering the various techniques that have revolutionized pipeline construction, food and beverage industry, and numerous other sectors requiring impeccable welds.

Tiêu Chuẩn Mối Hàn Và Phương Pháp Bảo Trì Hàn Tốt Nhất

Kiểm tra mối hàn để đánh giá chất lượng là điều vô cùng quan trọng không thể bỏ qua. Điều này nhằm đảm bảo về thẩm mỹ, chất lượng của mối hàn đẹp, bền, chắc chắn,.. Bên cạnh đó, việc sửa chữa, nâng cấp và bảo trì hàn (Maintenance work welding) cũng được hạn chế.

Components and Features of an Orbital Welding Machine

Contact Swisstech Schreiner if your business needs any information or solutions about orbital welding technology, equipment, orbital welding machines, orbital welding stainless steel pipe, installation and construction of industrial pipeline systems,...

Công nghệ hàn quỹ đạo (orbital welding technology) được thực hiện như thế nào?

Công nghệ hàn quỹ đạo (orbital welding technology) đã trở thành một công cụ quan trọng trong các lĩnh vực như hàng không vũ trụ, công nghiệp chế tạo, năng lượng tái tạo, ngành dược phẩm và ngành nước giải khát. Hãy theo dõi bài viết sau của Swisstech Schreiner để tìm hiểu công nghệ hàn quỹ đạo (orbital welding technology) được thực hiện như thế nào và những lợi ích khi ứng dụng nó nhé.

Các biện pháp an toàn trong công tác bảo trì (Maintenance work)

Công tác bảo trì đóng vai trò quan trọng trong công việc hàn hiện đại. Tuy nhiên, công việc này cũng tiềm ẩn khá nhiều nguy hiểm cho người thợ. Hãy theo dõi bài viết dưới đây của Swisstech Schreiner để biết được các biện pháp an toàn cho công tác bảo trì (Maintenance work) hàn quỹ đạo này nhé.

How to Use Orbital Welding Technology Properly: A Comprehensive Guide

Orbital welding technology, when done with the right techniques and attention to detail, can produce welds that are a perfect blend of strength and beauty. Embrace these techniques shared by Swisstech Schreiner, and let your welds be the benchmark of excellence.