In the age of technology-driven solutions, the art of welding has undergone significant transformation. Among the plethora of welding methods available, one technique that stands out is orbital welding technology. But what is it about this technology that's catching the attention of industries around the world? Join Swisstech Schreiner deeper into the world of orbital welding and unearth its unparalleled benefits.

Precision and Consistency at Its Best

One of the primary reasons to invest in orbital welding is its precision. The computer-controlled process ensures that each weld is consistent with the last, eliminating the inconsistencies often found in manual welding. This makes orbital welding an excellent choice for industries like orbital pharmaceutical, semiconductor, biology, and the food and beverage industry where precision is paramount.

Automation application

The automated nature of orbital welding technology reduces the need for manual intervention. This not only cuts down on human error but also means that once parameters are set, you can expect the same high-quality weld every single time. Moreover, automation facilitates continuous operations, leading to faster project completion.

Adaptability to Challenging Environments

Traditional welding techniques may not always be feasible in every scenario, especially in confined spaces or when working with intricate pipe structures. Orbital welding shines in such situations, ensuring that even the hardest-to-reach areas receive the same top-notch weld quality.

Lowering Costs in the Long Run

While the initial investment for orbital welding machines might be higher than traditional methods, the return on investment is substantial. Thanks to reduced wastage, fewer reworks, and minimized inspection requirements, businesses can expect to save significantly in the long run.

=> Read more : Orbital Welding Technology Standards in the Beverage Industry

Safety First

Another inherent benefit of orbital welding technology is its safety profile. Since the process is mostly automated, the chances of occupational hazards, such as burns or exposure to harmful fumes, diminish considerably. This not only ensures the well-being of the workforce but also translates to fewer worker compensation claims and downtime.

Staying Ahead in a Competitive Market

For businesses looking to maintain a competitive edge, staying updated with the latest technology is crucial. Embracing orbital welding not only enhances productivity and quality but also showcases your commitment to innovation and state-of-the-art solutions.

The decision to transition to orbital welding technology is not merely about adopting a new method; it's about ushering in a wave of efficiency, consistency, and quality. As industries evolve and demand only the best, isn't it time you considered the many benefits of orbital welding.

=> Read more at : Why Choose Orbital Welding Technology?

Swisstech Schreiner: Pioneering Solutions in Orbital Welding Technology for Industrial Pipeline Systems Construction

In the dynamic realm of industrial pipeline systems, the integration of advanced technologies is not just a luxury but a necessity. With the rising demand for precision, consistency, and reliability, orbital welding technology has emerged as the frontrunner in ensuring top-notch quality. Swisstech Schreiner, recognized for its innovative prowess, is at the forefront of integrating this technology, setting new benchmarks in the construction of industrial pipeline systems. Dive with us into the world of Swisstech Schreiner and discover how their expertise in orbital welding is transforming industries.

SwissTech Schreiner's Mastery in Orbital Welding

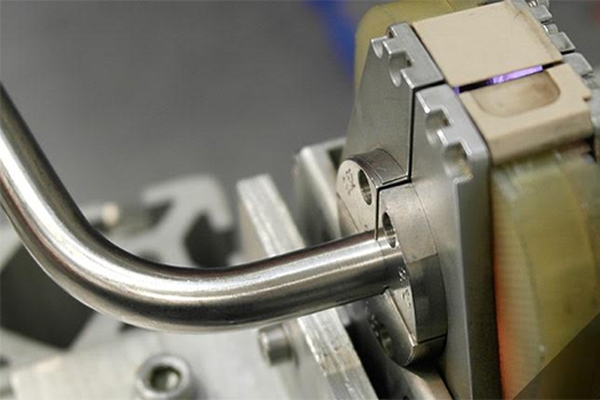

For those new to the concept, orbital welding is an automated welding technique where a torch mechanically rotates around a stationary workpiece, usually a pipe or tube. This ensures a consistent, high-quality weld that is often superior to manual welds. Given the critical nature of industrial pipelines – which often carry sensitive or hazardous materials – the uniformity and reliability provided by orbital welding are invaluable.

Swisstech Schreiner has recognized the potential of orbital welding and has invested significantly in mastering this technology. Their approach is not just about utilizing a new technique but optimizing it. By marrying their rich experience in pipeline systems construction with cutting-edge orbital welding technology, they offer solutions that are both innovative and proven.

Their systems are designed to tackle the most complex welding challenges, ensuring that each weld is consistent, durable, and meets the stringent standards required in various industries. By reducing human error and enhancing repeatability, Swisstech Schreiner ensures that every project they undertake stands as a testament to quality and resilience.

=> Read more : The Orbital Welding Technology in the Beverage Industry: Revolutionizing Quality and Efficiency

Tailored Solutions for Diverse Industries

What makes Swisstech Schreiner stand out is their ability to provide customized solutions. Understanding that the needs of a pharmaceutical company differ from those of a beverage producer, they've honed their expertise to cater to diverse industry requirements. Their orbital welding technology is adaptable, ensuring that whether it's high-volume production or intricate, specialized pipeline systems, Swisstech Schreiner has the technology and know-how to deliver.

Beyond just precision, Swisstech Schreiner's approach to orbital welding also emphasizes safety and sustainability. Their welding processes are designed to minimize risks, ensuring safe operations. Additionally, by ensuring the longevity and reliability of welds, they contribute to sustainable operations, reducing the need for frequent maintenance or replacements.

In Conclusion

Swisstech Schreiner's foray into the domain of orbital welding technology for the construction of industrial pipeline systems is not just about adopting a trend. It's about setting new industry standards and paving the way for a future where precision, reliability, and sustainability are the cornerstones. Contact us to discuss the best options for your business.

Swisstech Schreiner.

Add: ch 4153 reinach and hcm city vietnam

Hotline: (+84) 931 - 386 - 062

Phone: (+84) 931 - 386 - 062 +84931386062 ( zalo / viber / whatsapp )

Email: swiss.tech.schreiner@gmail.com

Other News

Vì sao nên gia công ống thép không gỉ (Stainless steel pipe processing) bằng máy hàn quỹ đạo?

Tại sao nên sử dụng máy hàn quỹ đạo trong quá trình gia công thép không gỉ (Stainless steel pipe processing)? Hãy cùng Swisstech Schreiner tìm hiểu gia công thép không gỉ là gì? Máy hàn quỹ đạo là gì? Và những lợi ích khi gia công thép không gỉ bằng máy hàn quỹ đạo tại ở bài viết sau nhé.

Reasons why orbital welding machines are suitable for pipe welding

Orbital welding machines have revolutionized the pipe welding industry with their precision, efficiency, and unmatched consistency. Join Swisstech Schreiner as we uncover the reasons behind the orbital welding technology growing prevalence and how they could be the key to unlocking new levels of excellence in pipe welding.

Tầm Quan Trọng Của Việc Bảo Trì Máy Hàn Maintenance work welding

Khám phá lịch trình bảo trì định kỳ cho máy hàn Maintenance work welding để đảm bảo hiệu suất tối ưu và an toàn cao nhất. Từ bảo trì hàng giờ đến hàng năm, hãy tìm hiểu cách giữ cho thiết bị của bạn hoạt động mượt mà. Liên hệ Swisstech Schreiner để biết thêm chi tiết và hỗ trợ

Công nghệ hàn quỹ đạo cho đường ống kích thước lớn

Cùng Swisstech Schreiner khám phá công nghệ hàn quỹ đạo Orbital welding technology tiên tiến dành cho đường ống kích thước lớn, một giải pháp hiệu quả và đáng tin cậy để đảm bảo mối hàn chất lượng cao và độ bền vượt trội.

Bảo trì nhà máy sản xuất đồ uống

Bảo trì nhà máy đồ uống đóng vai trò then chốt trong việc đảm bảo dây chuyền sản xuất hoạt động ổn định, giảm thiểu sự cố và tối ưu hóa hiệu suất vận hành.

Các kỹ thuật hàn quỹ đạo trong ống dẫn dược phẩm

Các kỹ thuật hàn quỹ đạo - Orbital welding technology cung cấp giải pháp lý tưởng cho các thách thức về vệ sinh và kín khí trong môi trường sản xuất dược phẩm. Bài viết này của Swisstech Schreiner sẽ khám phá chi tiết về các kỹ thuật hàn quỹ đạo phổ biến.