The beverage industry is much more than the refreshing drink production that you sip on. Behind that invigorating taste is an intricate network of processing, manufacturing, and delivery mechanisms that must be impeccable in their operation. Among these mechanisms, the role played by welding, particularly orbital welding, is pivotal. If you've ever wondered about the rigorous standards behind the drinks you consume, let's Swisstech Schreiner dive deep into the significance of orbital welding technology standards in the beverage sector.

What is Orbital Welding Technology?

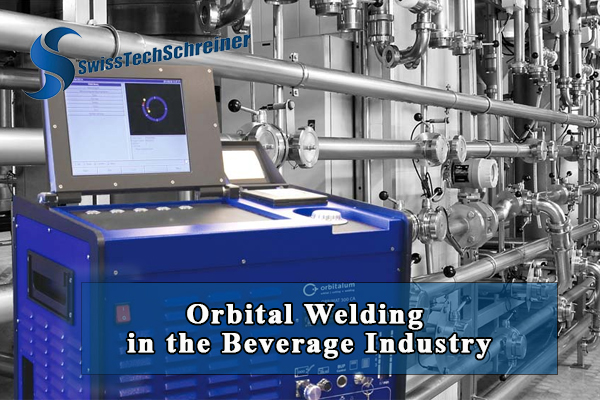

Orbital welding technology is an automated welding technique that utilizes specialized equipment to rotate the welding arc around a stationary workpiece, most often tubes or pipes. This ensures a uniform, high-quality weld that is consistent, reliable, and free from potential contaminants or inconsistencies.

Why is Orbital Welding Technology Preferred in the Beverage Industry?

Sanitary Standards: The beverage industry is one governed by strict sanitary guidelines. Contaminants can have dire consequences, from affecting taste to introducing health risks. Traditional welding methods can result in irregularities or crevices in pipes where bacteria can thrive. Orbital welding technology, on the other hand, creates smooth, consistent, and crevice-free welds, making them resistant to bacterial growth.

Reliability: Orbital welding technology is an automated process, eliminating the inconsistencies associated with manual welding. This guarantees that every weld is executed with the same precision, ensuring the reliability and safety of beverage production lines.

High Production Rates: Due to its automated nature, orbital welding technology can maintain high production rates. This is especially useful in the beverage industry, which often requires extensive piping systems for large-scale production facilities.

The Process of Orbital Welding in the Beverage Industry

The orbital welding process begins by enclosing the pieces to be welded within a welding head. An electric arc is then formed from a tungsten electrode, which moves in a circular motion around the pipe, creating a perfect circumferential weld. The use of shielding gas, like argon, ensures that contaminants are kept at bay during the welding process.

=> Read more at : Beverage Industry Use Orbital Welding Technology Application

The Benefits Beyond Just Welding

While the primary benefit of orbital welding technology is the high-quality welds it produces, the technology brings along other advantages:

Cost-Efficiency: With reduced weld failures and the elimination of rework, the overall cost savings over time can be significant.

Reduced Training Costs: While the initial setup and programming of orbital welding machines may require specialized knowledge, the need for multiple skilled manual welders is decreased, leading to reduced training expenses.

Flexibility: Modern orbital welding equipment can be programmed to handle various sizes and specifications, making it a versatile tool for different production requirements.

Orbital welding technology is revolutionizing the beverage industry by providing a solution that ensures product purity, operational efficiency, and unmatched consistency. As consumer demand for safety and quality in beverages continues to rise, we can only expect the adoption of such sophisticated technologies to become more widespread. If your business in the beverage industry is in need of pipeline system construction and installation using orbital welding technology, please contact Swisstech Schreiner for advice and support.

=> Read more about the Pipeline Construction in beverage industry at :

=> Orbital welding technology in the Pipeline Construction in beverage industry

Meets on-site standards in the beverage industry with orbital welding technology

The stringent requirements of the beverage industry mean that specific standards guide orbital welding processes:

Surface Finish: The interior surface of welded tubes and pipes should be smooth, free from ridges, and have a finish that matches or exceeds the parent material. This ensures that there's minimal buildup or deposition inside the tubes, which can affect beverage flow or quality.

Inspection and Validation: The beverage industry often uses borescopes or other visual inspection tools to confirm the integrity of orbital welds. Some even employ advanced techniques like X-ray or ultrasonic testing for a more detailed assessment.

Documentation: Every weld, its parameters, and results are meticulously documented. This provides a clear traceability record, ensuring accountability and aiding in quality assurance.

Training and Qualification: Only certified welders, trained in the specifics of orbital welding for the beverage industry, are allowed to oversee or maintain the equipment. This ensures that the highest quality standards are upheld.

Orbital welding technology standards have firmly cemented their place in the beverage industry. The emphasis on purity, precision, and consistency ensures that the drinks we consume are not just delightful but also safe. To make sure that there's an amalgamation of advanced technology and rigorous standards at play, bringing customers that unparalleled taste and quality, contact Swisstech Schreiner for advice and support.

Swisstech Schreiner.

Add: ch 4153 reinach and hcm city vietnam

Hotline: (+84) 931 - 386 - 062

Phone: (+84) 931 - 386 - 062 +84931386062 ( zalo / viber / whatsapp )

Email: swiss.tech.schreiner@gmail.com

Other News

Advantages of Orbital Welding Technology Versus Manual Welding

In this article, we will examine the numerous advantages orbital welding technology has over manual welding. Orbital welding machines can work faster, achieve higher weld quality, reduce errors and rework, improve worker safety, and lower overall operating costs. Join Swisstech Schreiner to learn about the benefits of orbital welding technology compared to manual welding through the following article.

Status and services of the shipbuilding industry in Vietnam

In addition to providing pipe welding services with orbital welding technology for stainless steel pipeline systems for the beverage industry, pharmaceutical industry, chemical, shipbuilding, etc., Swisstech Schreiner also provides solutions and services in the field of shipbuilding and yachting.

Considerations for Orbital Welding Technology in BioProcess Piping Application

Embracing the future of bioprocessing with open arms, Swisstech Schreiner provides more than just Orbital Welding Technology services; Their unwavering commitment to quality, precision, and adherence to industry standards makes them a trusted partner for bio-manufacturers around the globe.

Advantages and Disadvantages Of Orbital Welding Technology

Orbital welding technology has myriad advantages while also navigating the disadvantages that businesses must consider. Join Swisstech Schreiner as we explore the intricate dance of pros and cons that orbit around this futuristic welding technology.

Tầm Quan Trọng Khi Dùng Hàn Orbital Trong Gia Công Ống Thép Không Gỉ

Khám phá tầm quan trọng của ứng dụng hàn orbital cho việc gia công ống thép không gỉ Stainless steel pipe processing. Tìm hiểu thêm về các ưu điểm chuyên sâu của máy hàn quỹ đạo từ Swisstech Schreiner.

Stainless Steel Pipe Processing và Hàn Quỹ Đạo: Giải Pháp Gia Công Tối Ưu Cho Thép Không Gỉ 904L

Giải Pháp Gia Công Tối Ưu Cho Thép Không Gỉ 904L.Sự đầu tư bài bản vào quy trình gia công và công nghệ hàn chính là chìa khóa nâng cao năng lực sản xuất, giảm thiểu lỗi kỹ thuật và đảm bảo tuổi thọ vận hành lâu dài cho toàn hệ thống.