Orbital welding machines have revolutionized the welding industry, providing precision and efficiency in various welding applications. These machines are designed to perform automated welding, eliminating the need for manual labor and reducing the risk of human error. With the increasing demand for high-quality welds in industries such as aerospace, automotive, and oil and gas, orbital welding machines have become an essential tool for many businesses.

If you are considering purchasing an orbital welding machine or hire services related to orbital welding machines there are several factors to consider to ensure that you make the right investment. In this blog post, Swiss Tech Schreiner will discuss everything you need to know about orbital welding machines, including their prices, where to find them for sale, and services related to these machines.

Factors to Consider When Purchasing an Orbital Welding Machine

When it comes to investing in an orbital welding machine, there are several factors to consider to ensure that you get the best value for your money. Here are some essential factors to keep in mind when purchasing an orbital welding machine:

Type of Welding Application

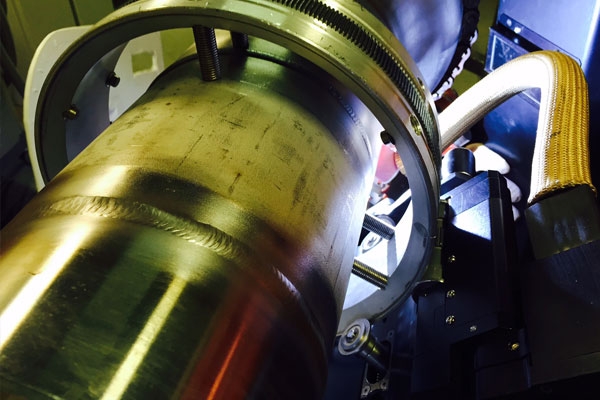

The first thing to consider is the type of orbital welding technology application you will be using the machine for. Orbital welding machines come in different types, each designed for specific welding applications. For instance, if you need to weld pipes or tubes, you will need a machine with a narrow head that can fit into tight spaces. On the other hand, if you need to weld large structures, you will need a machine with a larger head and longer reach.

Welding Material and Thickness

Another crucial factor to consider is the material and thickness of the metal you will be welding. Different orbital welding machines are designed to handle different materials and thicknesses. For example, some machines are better suited for welding stainless steel, while others are more suitable for aluminum or titanium. Additionally, the thickness of the material will determine the power and capabilities of the machine you need.

Welding Environment

The welding environment also plays a significant role in determining the type of orbital welding machine you need. If you will be working in a hazardous or confined space, you will need a machine that is specifically designed for such environments. These machines are equipped with safety features and can withstand extreme temperatures and conditions.

Automation and Control Features

One of the main advantages of orbital welding machines is their automation and control features. These machines are equipped with advanced technology that allows for precise and consistent welds. When purchasing an orbital welding machine, make sure to consider the automation and control features it offers, such as programmable settings, remote control, and data logging capabilities.

Brand and Reputation

When investing in any equipment, it is essential to consider the brand and reputation of the manufacturer. Look for reputable brands with a proven track record in producing high-quality orbital welding machines. You can also read reviews and ask for recommendations from other businesses in your industry to ensure that you are making the right choice.

Cost and Return on Investment

Of course, the cost of the orbital welding machine is a crucial factor to consider. However, it is essential to look beyond the initial price and consider the long-term return on investment. A high-quality orbital welding machine may have a higher upfront cost, but it will save you money in the long run by reducing labor costs, improving efficiency, and producing high-quality welds.

Where to Find Orbital Welding Machines for Sale - Swisstech Schreiner

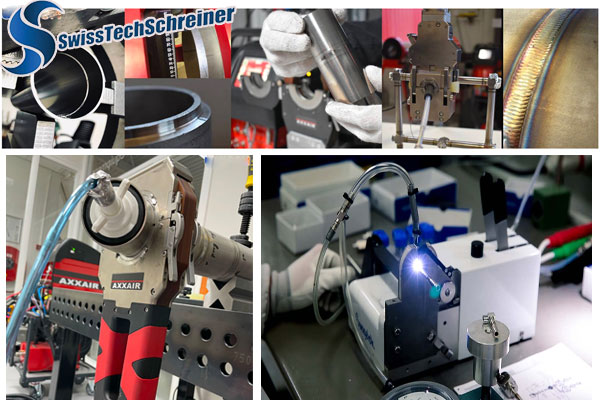

Now that you know what factors to consider and the average prices of orbital welding machines, the next question is where to find them for sale. One of the most reputable and trusted suppliers of orbital welding machines is Swisstech Schreiner.

Swisstech Schreiner is a leading supplier of high-quality welding equipment, including orbital welding machines. They offer a wide range of machines from top brands such as Polysoude, Arc Machines, and Magnatech. Their team of experts can help you choose the right machine for your specific needs and provide training and support to ensure that you get the most out of your investment.

In addition to selling orbital welding machines, Swisstech Schreiner also offers rental services for businesses that need a machine for a short period. This is a cost-effective option for companies that have occasional welding projects or want to try out a machine before making a purchase.

=> Read more at :

=> Components and Features of an Orbital Welding Machine

=> Reasons why orbital welding machines are suitable for pipe welding

=> Comparing Orbital Welding Machine and Traditional Welding Methods

Services Related to Orbital Welding Machine

Aside from purchasing or renting an orbital welding machine, there are other services related to these machines that can benefit your business. Here are some of the services offered by Swisstech Schreiner:

Training and Support

Orbital welding machines require proper training and expertise to operate effectively. Swisstech Schreiner offers training programs for businesses and individuals who want to learn how to use these machines. They also provide ongoing support and maintenance services to ensure that your machine is always in top condition.

Customization and Integration

If you have specific requirements for your welding applications, Swisstech Schreiner can customize and integrate orbital welding machines to meet your needs. This includes adding additional features or modifying the machine's capabilities to suit your welding environment and materials.

Consultation and Project Management

Swisstech Schreiner has a team of experienced engineers and technicians who can provide consultation and project management services for businesses looking to implement orbital welding techonology solutions. They can help with everything from planning and design to installation and maintenance, ensuring that your welding projects run smoothly and efficiently.

Maintenance and Repair of Orbital Welding Machines Services

Like any other equipment, orbital welding machines require regular maintenance and occasional repairs to ensure their longevity and performance. Swisstech Schreiner offers maintenance and repair services for all types of orbital welding machines. Their team of experts can diagnose and fix any issues with your machine, ensuring that it continues to operate at its best.

In addition to maintenance and repair services, Swisstech Schreiner also offers calibration and certification services for orbital welding machines. This is essential for businesses that need to comply with industry standards and regulations.

Conclusion

Orbital welding machines are a valuable investment for businesses in various industries. They offer precision, efficiency, and automation, making them an essential tool for producing high-quality welds. When purchasing an orbital welding machine, make sure to consider factors such as the type of welding application, material and thickness, welding environment, automation and control features, brand and reputation, and cost and return on investment.

Swisstech Schreiner is a trusted supplier of orbital welding machines, offering a wide range of options from top brands. They also provide training, customization, consultation, and maintenance services related to these machines. With their expertise and support, you can ensure that your orbital welding machine operates at its best and helps your business thrive.

Swisstech Schreiner.

Add: ch 4153 reinach and hcm city vietnam

Hotline: (+84) 931 - 386 - 062

Phone: (+84) 931 - 386 - 062 +84931386062 ( zalo / viber / whatsapp )

Email: swiss.tech.schreiner@gmail.com

Other News

Ứng Dụng Công Nghệ Hàn Quỹ Đạo Trong Ngành Công Nghiệp Đồ Uống

Ngành công nghiệp đồ uống sử dụng công nghệ hàn quỹ đạo không chỉ là xu hướng mà còn là giải pháp bắt buộc trong bối cảnh tiêu chuẩn vệ sinh và hiệu quả sản xuất ngày càng được siết chặt. Nhờ khả năng tạo mối hàn sạch, chính xác và đồng đều, công nghệ này giúp các doanh nghiệp nâng cao chất lượng sản phẩm

The stainless steel pipe processing

Swisstech Schreiner is always proud to be the leader in the field of stainless steel pipe processing with a team of experienced employees. We offer solutions about the stainless steel pipe processing for pipeline systems and services related to maintenance work and orbital welding technology.

Những Sai Lầm Thường Gặp Gây Mài Mòn Thiết Bị Hàn Quỹ Đạo

Máy hàn quỹ đạo (Orbital welding machine) tạo ra mối hàn có độ chính xác và độ tin cậy cao, đây là yếu tố cần thiết đối với các chuyên gia trong ngành hàng không vũ trụ, dược phẩm và chế biến thực phẩm. Việc bảo trì mối hàn thường xuyên giúp hệ thống tạo ra mối hàn đồng nhất, sạch và hiệu suất cao.

Kiểm soát chất lượng và an toàn khi sử dụng hàn quỹ đạo

Bài viết này của Swisstech Schreiner nhằm mục đích cung cấp một cái nhìn sâu sắc về các nguyên tắc và phương pháp tốt nhất để đảm bảo kiểm soát chất lượng và an toàn tối ưu khi sử dụng máy hàn quỹ đạo Orbital welding machine.

Dịch vụ bảo dưỡng thiết bị công nghiệp chuyên nghiệp

Swisstech Schreiner cung cấp dịch vụ bảo dưỡng thiết bị công nghiệp chuyên nghiệp, định kỳ theo tháng, quý, năm giúp nhà máy duy trì hoạt động ổn định, tăng tuổi thọ máy móc và giảm thiểu sự cố phát sinh.

The Advantages and Applications of Orbital Welding Machines in the Manufacturing Industry

What exactly are these machines, and how do they stand out in the crowded field of manufacturing tools? Join Swisstech Schreiner to dive into the fascinating world of orbital welding machines, the automated marvels of the welding world.