Orbital welding machines represent a specialized segment of welding equipment designed to provide high-quality and consistent welds, particularly in environments where precision and repeatability are paramount. This article from Swisstech Schreiner writes about the features, applications, and technological advancements of orbital welding machines, illustrating their importance in various industrial sectors.

Introduction to Orbital Welding Technology

Orbital welding is an automated welding process that utilizes specialized equipment to rotate the welding arc around a stationary workpiece, typically a pipe or tube. This method contrasts with traditional welding, where the workpiece or the welding torch is manually manipulated. The automation in orbital welding technology ensures high precision and repeatability, essential in industries where weld integrity is critical.

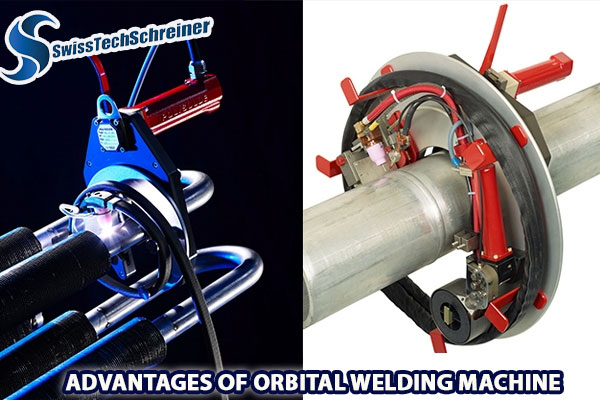

Components of an Orbital Welding Machine

Power Supply: The power supply unit controls the welding parameters like current, voltage, and welding speed.

Weld Head: This component holds and rotates the welding torch around the workpiece.

Control System: A sophisticated control system, often with a programmable interface, allows for precise adjustments of welding parameters.

Wire Feed Mechanism: In some orbital welding systems, a mechanism feeds the welding wire automatically.

This advanced feature seamlessly feeds the welding wire into the weld pool, ensuring a steady and uninterrupted welding process, thus enhancing both the efficiency and the integrity of the welds. Together, these components form the backbone of orbital welding machines, embodying technological sophistication and offering unparalleled precision in critical welding operations.

Applications of Orbital Welding Technology

Orbital welding machines have carved a niche in various industries, becoming an indispensable tool wherever the utmost quality in pipe and tubing welds is demanded. In the aerospace sector, these machines play a pivotal role, delivering precision welds essential for aircraft components and fuel lines, where the slightest flaw can have significant consequences. The pharmaceutical industry, too, relies on orbital welding pharmaceutical creating sterile piping systems, ensuring the purity and safety of medical products. Similarly, in semiconductor manufacturing, orbital welding is crucial for assembling ultra-high-purity systems, a testament to its ability to maintain the highest standards of cleanliness and precision.

The robustness of orbital welding also extends to the demanding environments of the oil and gas industry, where it is employed in both onshore and offshore pipeline welding, a testimony to its versatility and reliability. Furthermore, the food and beverage industry, orbital welding is the method of choice for constructing critical piping systems, underlining its importance in sectors where safety and precision are paramount. This widespread application across diverse and critical industries underscores the versatility and reliability of orbital tig welding machines, making them a cornerstone in modern industrial operations.

Advantages of Orbital Welding Machine

Orbital welding machine stands out in the welding landscape for its exceptional blend of benefits, primarily driven by its automation capabilities. This technology shines in delivering consistent quality, as its automated controls are finely tuned to produce uniform welds with remarkable precision, a feature that’s crucial in applications demanding high standards. The automation aspect also significantly diminishes the likelihood of human error, a vital factor in maintaining the integrity of welds.

Moreover, this mechanized approach contributes to enhanced efficiency, outpacing manual welding in terms of speed and reducing the overall time taken for projects. Orbital welding's adaptability is another feather in its cap, capable of handling a diverse range of materials and accommodating various pipe diameters, making it a versatile tool in a welder's arsenal.

Additionally, a pivotal advantage of orbital welding technology is the heightened safety it offers. By reducing the welder's direct exposure to potentially hazardous conditions, orbital welding not only ensures the safety of the personnel but also contributes to a safer work environment. This amalgamation of consistent quality, reduced error, efficiency, flexibility, and safety makes orbital welding a highly sought-after solution in industries where welding is a critical component of operations.

Technological Advancements

The landscape of orbital welding technology has been revolutionized by a series of recent advancements, marking a significant leap forward in its capabilities and applications. A key development is the integration with digital systems, which has transformed the way welding operations are monitored and controlled. By harnessing digital interfaces, operators can now enjoy enhanced oversight and precision in their welding tasks, making the process more efficient and reliable. Complementing this technological stride is the evolution of welding heads. These have become more compact and versatile, broadening the scope of their application and allowing them to adapt to a variety of welding scenarios with ease.

Furthermore, the leap in programming capabilities stands out as a monumental advancement. Modern automatic orbital welding machines are now equipped to handle complex weld patterns and intricate parameter adjustments, providing an unprecedented level of control over the welding process. Additionally, the advancements in remote operation capabilities have opened new frontiers, particularly in executing welding tasks in environments that are hazardous or difficult to access.

This not only enhances safety but also extends the utility of orbital welding technology to previously challenging locales. Collectively, these innovations have not only elevated the efficiency and scope of orbital welding but have also positioned it as a cutting-edge tool in the welding industry, ready to meet the ever-evolving demands of modern manufacturing and construction projects.

=> See more articles on the same topic at :

=> Reasons why orbital welding machines are suitable for pipe welding

=> Choosing the right pipe welding method?- Orbital welding machine

Challenges and Future Trends

While orbital welding machines offer numerous advantages, they also present challenges such as the high initial investment and the need for skilled operators to program and maintain the machines. Future trends in orbital welding technology may include greater automation, integration with artificial intelligence for adaptive welding processes, and further miniaturization of equipment.

Conclusion

Orbital welding machines have revolutionized welding in industries where precision and consistency are non-negotiable. As technology continues to evolve, these machines are set to become even more integral in various industrial processes, offering solutions that combine efficiency, quality, and safety. Contact Swisstech Schreiner if your business needs any information or solutions about orbital welding technology, equipment, orbital welding machines, orbital welding stainless steel pipe, installation and construction of industrial pipeline systems,...

Swisstech Schreiner.

Add: ch 4153 reinach and hcm city vietnam

Hotline: (+84) 931 - 386 - 062

Phone: (+84) 931 - 386 - 062 +84931386062 ( zalo / viber / whatsapp )

Email: swiss.tech.schreiner@gmail.com

Other News

Máy hàn quỹ đạo là gì? Cấu tạo, nguyên lý và ứng dụng trong các ngành công nghiệp hiện đại

Trong sản xuất công nghiệp, đặc biệt là các lĩnh vực yêu cầu cao về độ sạch và độ chính xác như dược phẩm, thực phẩm, hóa chất và công nghệ sinh học, việc tạo ra các mối hàn chất lượng cao là điều tối quan trọng. Để đáp ứng yêu cầu này, công nghệ hàn quỹ đạo tự động đã ra đời và ngày càng khẳng định vai trò không thể thay thế

Bảo trì trong ngành nước giải khát (Beverage industry)

Bảo trì là một hoạt động không thể thiếu trong ngành nước giải khát, vì nó ảnh hưởng trực tiếp đến chất lượng và an toàn của các sản phẩm dành cho người tiêu dùng. Tuy nhiên, việc bảo trì cũng gặp phải nhiều khó khăn và thách thức do các yêu cầu quy định nghiêm ngặt, các thiết bị sản xuất phức tạp. Trong bài viết này Swisstech Schreiner sẽ chia sẻ tầm quan trọng trong công việc bảo trì (Maintenance work) và quy trình bảo trì cho ngành nước giải khát (Beverage industry) hiệu quả nhất nhé.

Các lỗi mối hàn xấu và cách khắc phục nhanh chóng, hiệu quả

Khám phá các lỗi mối hàn xấu thường gặp và cách khắc phục nhanh chóng, hiệu quả. Đảm bảo chất lượng, độ bền khi gia công ống thép không gỉ Stainless steel pipe processing cho các công trình và an toàn trong sản xuất cùng Swisstech Schreiner.

Construction of pipeline systems in the beverage industry

Let's Swisstech Schreiner discover the intricate process behind constructing efficient pipeline systems tailored for the dynamic demands of the beverage industry. Explore key techniques (orbital welding machine), and considerations for ensuring seamless liquid transport, hygiene, and quality.

Bảo trì định kỳ máy hàn quỹ đạo - Maintenance work

Liên hệ với Swisstech Schreiner để được tư vấn và nhận giải pháp bảo trì toàn diện cho hệ thống hàn quỹ đạo của bạn. Chúng tôi luôn sẵn sàng đồng hành cùng doanh nghiệp trong hành trình vận hành bền vững và hiệu quả.

Cách ngăn ngừa lỗi thiếu nóng chảy để đảm bảo mối hàn chất lượng cao

Hàn quỹ đạo giúp tạo ra mối hàn chính xác, nhưng lỗi thiếu nóng chảy có thể gây nguy hiểm. Tìm hiểu nguyên nhân, cách khắc phục và giải pháp từ Swisstech Schreiner để đảm bảo mối hàn chất lượng cao!