Orbital welding technology, a specialized arena in the world of welding, offers precision and repeatability in applications where standard welding processes fall short. In industries like aerospace, semiconductor, and pharmaceutical, where tube and pipe welding require utmost accuracy, orbital welding reigns supreme. If you're considering integrating this technology or improving your existing processes, read on the following article by Swisstech Schreiner to understand how to use orbital welding technology properly.

Orbital welding technology in industries

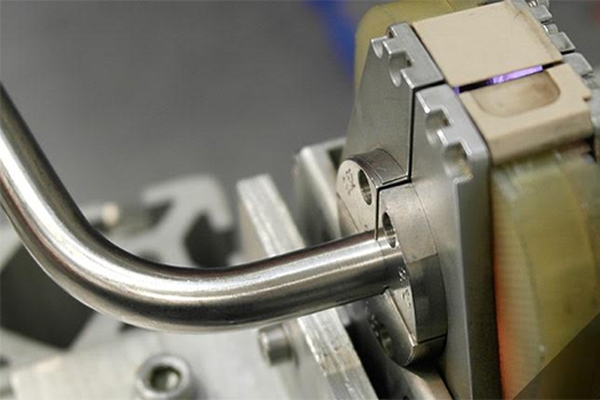

Orbital welding technology is an automated welding process that utilizes a tungsten electrode rotating (or orbiting) around a stationary workpiece, typically a tube or pipe. This automation ensures uniform welds, reduces the chances of errors, and can lead to higher production rates compared to manual welding.

Steps to Use Orbital Welding Technology Properly

Choosing the Right Tools and Setup for Orbital Welding:

When setting up for orbital welding, it's crucial to pick tools and components tailored to your specific task. Start by opting for a power supply that aligns with the requirements of your orbital welding job. Next, based on the tubes' or pipes' diameter and thickness, select a weld head that's a perfect fit. Don't forget about the shielding gas; always go for high-purity variants, and fine-tune the flow rate for optimum results.

The Importance of Preparation:

Before diving into orbital welding technology, prepping your materials can make all the difference. The welding zone should be free from any impurities. So, whether it's by manual scrubbing, using chemical agents, or employing a mix of both, ensure your materials are pristine. Additionally, precise alignment is vital. Any discrepancies in positioning can lead to defects, so always double-check that your tubes or pipes are correctly set in their fixture.

Configuring Your Weld Settings:

Setting up your weld parameters requires a thorough understanding of your material. Factors like its thickness dictate the amperage, voltage, and travel speed. If in doubt, the equipment's user guide or a seasoned welding engineer can offer invaluable insights. Contemporary orbital welding equipment comes equipped with multi-segment programming capabilities, offering enhanced control over the welding procedure. It's also a good practice to conduct test welds on excess material before the main operation, ensuring that your chosen settings are spot on.

Maintenance and Quality Assurance:

For the longevity and efficiency of your orbital welding machine, regular upkeep is non-negotiable. This includes cleaning the weld head, replacing parts showing wear and tear, and ensuring the tungsten electrode is not only sharp but also perfectly centered.

But, it's not just about the tools; the end product's quality is paramount. Therefore, always document the parameters used for every weld. This meticulous record-keeping is indispensable, especially in sectors where every step needs accounting for. And, to be doubly sure of your weld's quality, utilize non-destructive evaluation methods like X-ray or ultrasonic tests.

=> See more articles on the same topic at:

=> Application of Orbital Welding Technology in the Construction of Industrial Pipeline Systems

=> The reason for using an Orbital Welding technology

=> The Orbital Welding Technology in the Beverage Industry: Revolutionizing Quality and Efficiency

Mastering the Art of Orbital Welding for Flawless Results

Orbital welding technology, with its advanced technology and precise techniques, can produce welds that are not only structurally sound but also aesthetically pleasing. For those looking to achieve beautiful welds using orbital welding machines, certain methodologies can make all the difference.

Prioritize Surface Preparation:

The canvas for your welding art is the surface of the materials you're joining. Just as an artist wouldn’t paint on a dirty canvas, welders shouldn't work on unprepared surfaces. Dedicate time to thorough cleaning, ensuring the removal of any oxides, contaminants, or residues. The cleaner the metal, the smoother and more appealing the weld bead will appear.

Utilize Pulse Welding:

Pulse welding is a game-changer for achieving neat welds. By controlling the heat input and allowing cooler periods between pulses, you get a more controlled weld pool. The result? Uniform and beautiful ripple patterns that are a hallmark of top-tier welding work.

Consistent Travel Speed:

A steady hand ensures a consistent travel speed, leading to an even bead without over-penetration or undercutting. For a weld that looks as good as it holds, maintaining an unwavering speed is essential. Many modern orbital welding machines come with features that help regulate this, so be sure to leverage them.

Optimize Gas Shielding:

A proper shielding gas flow ensures protection from atmospheric contaminants. By selecting the right type and ensuring its consistent flow, you can prevent discoloration and achieve that shiny, silver finish on your welds.

Post-Weld Polishing:

For welds that truly shine, consider a post-weld polishing or passivation process. This not only enhances the weld's appearance but also helps in preventing corrosion, especially for stainless steel.

Regular Equipment Checks:

Remember, even the best techniques can falter with sub-par equipment. Regularly inspect and maintain your orbital welding machine. A well-maintained machine ensures consistent energy output and precise control, both critical for beautiful welds.

Orbital welding technology, when done with the right techniques and attention to detail, can produce welds that are a perfect blend of strength and beauty. As the world of welding evolves, blending art with science can set you apart. Embrace these techniques shared by Swisstech Schreiner, and let your welds be the benchmark of excellence.

Remember, like any technology, the key to success with orbital welding technology is a combination of the right equipment, proper training, and consistent practice.

Swisstech Schreiner.

Add: ch 4153 reinach and hcm city vietnam

Hotline: (+84) 931 - 386 - 062

Phone: (+84) 931 - 386 - 062 +84931386062 ( zalo / viber / whatsapp )

Email: swiss.tech.schreiner@gmail.com

Other News

Lý Do Tại Sao Hàn Orbital Được Tin Dùng Trong Ngành Sữa

Ngày nay, hàn công nghệ quỹ đạo orbital welding technology đang trở thành xu hướng nổi bật trong nhiều ngành công nghiệp, đặc biệt là trong ngành sản xuất sữa. Hãy cùng tìm hiểu thêm chi tiết về công nghệ hàn thông qua bài sau.

Dịch vụ bảo dưỡng thiết bị công nghiệp chuyên nghiệp

Swisstech Schreiner cung cấp dịch vụ bảo dưỡng thiết bị công nghiệp chuyên nghiệp, định kỳ theo tháng, quý, năm giúp nhà máy duy trì hoạt động ổn định, tăng tuổi thọ máy móc và giảm thiểu sự cố phát sinh.

Quy trình bảo trì hàn (Maintenance work welding Process)

Trong quá trình sử dụng, các kết cấu hàn có thể bị hư hỏng hoặc xuống cấp do các yếu tố như thời tiết, tác động cơ học hoặc quá trình ăn mòn. Do đó, việc bảo trì hàn (Maintenance work welding) thường xuyên là rất cần thiết. Hãy cùng Swisstech Schreiner tìm hiểu quy trình bảo trì hàn qua bài viết sau.

Những Sai Lầm Thường Gặp Gây Mài Mòn Thiết Bị Hàn Quỹ Đạo

Máy hàn quỹ đạo (Orbital welding machine) tạo ra mối hàn có độ chính xác và độ tin cậy cao, đây là yếu tố cần thiết đối với các chuyên gia trong ngành hàng không vũ trụ, dược phẩm và chế biến thực phẩm. Việc bảo trì mối hàn thường xuyên giúp hệ thống tạo ra mối hàn đồng nhất, sạch và hiệu suất cao.

Vì sao nên gia công ống thép không gỉ (Stainless steel pipe processing) bằng máy hàn quỹ đạo?

Tại sao nên sử dụng máy hàn quỹ đạo trong quá trình gia công thép không gỉ (Stainless steel pipe processing)? Hãy cùng Swisstech Schreiner tìm hiểu gia công thép không gỉ là gì? Máy hàn quỹ đạo là gì? Và những lợi ích khi gia công thép không gỉ bằng máy hàn quỹ đạo tại ở bài viết sau nhé.

Công nghệ hàn quỹ đạo ngành thực phẩm và dược phẩm

Khám phá công nghệ hàn quỹ đạo Orbital welding technology tiên tiến của Swisstech Schreiner, giải pháp tối ưu cho ngành thực phẩm và dược phẩm, đảm bảo chất lượng và hiệu quả sản xuất cao nhất.