In today's fast-evolving world, where technology permeates every facet of our lives, the beverage industry is no exception. As demands for production efficiency, quality, and safety skyrocket, the industry is tapping into innovations to keep up. One such technological marvel transforming the beverage sector is orbital welding technology. But what exactly is orbital welding, and why is it applicable in the beverage industry ? Let's learn about this technology with Swisstech Schreiner through the following article

What is Orbital Welding Technology?

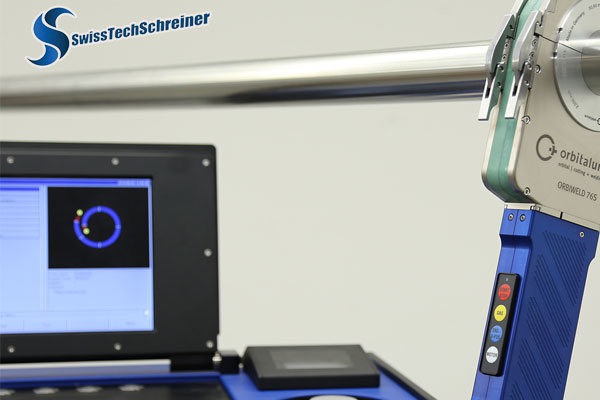

Orbital welding technology is an advanced welding method where the arc rotates mechanically, 360 degrees, around a stationary workpiece in a continuous process. This method uses specialized equipment, often computer or controller-operated, to ensure precision, repeatability, and high-quality welds.

Benefits of Orbital Welding in the Beverage Industry

Consistent Quality: As the process is automated, orbital welding minimizes human error, ensuring every weld maintains a consistent quality. This is vital in the beverage industry, where even minor inconsistencies can lead to contamination or product loss.

Efficiency and Speed: Traditional welding methods are time-consuming. With the automated approach of orbital welding, production rates are significantly improved, enabling faster project completion.

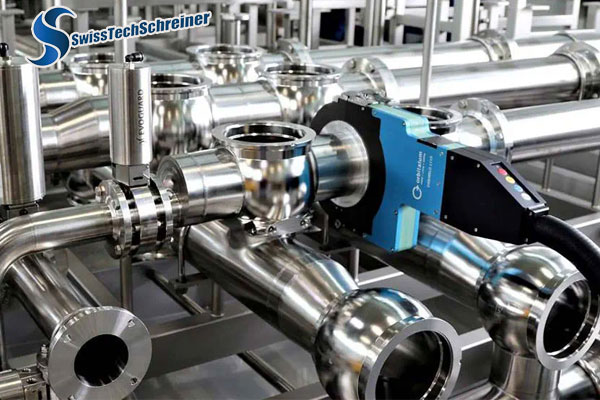

Hygiene and Safety: The beverage industry is bound by strict hygiene standards. Orbital welding produces clean, smooth, and pore-free weld seams, minimizing areas where bacteria can thrive. The reduced human intervention also means less risk of contamination.

Versatility: Whether it's stainless steel pipelines for transferring liquids or tanks for storage, orbital welding can handle varied applications within the beverage production line.

=> Read more : Orbital Welding Technology Standards in the Beverage Industry

The Competitive Edge

With the rise in consumer awareness about product safety and quality, brands are in a continuous battle to gain trust. Implementing orbital welding technology assures consumers of the brand's commitment to delivering the highest quality beverages.

Moreover, as companies strive to reduce production costs without compromising on quality, the efficiency and reliability of orbital welding provide a clear advantage. Less waste, reduced rework, and faster production times can lead to significant cost savings.

The fusion of technology and traditional sectors like the beverage industry showcases how innovations can drive remarkable improvements. Orbital welding technology, with its promise of efficiency, quality, and safety, is setting new benchmarks in beverage production standards. For those in the industry, staying updated with such advancements isn't just beneficial—it's essential to remain competitive and relevant in a market driven by consumer demands and technological progress.

Are you a part of the beverage industry or simply curious about the latest tech trends? Stay tuned for more insights and updates on how technology is shaping our world!

=> Read more : Construction of pipeline systems in the beverage industry

Constructing Stainless Steel Piping Systems in the Beverage Industry with Swisstech Schreiner

The beverage industry, always a hub of innovation and cutting-edge techniques, is now undergoing a transformation, courtesy of orbital welding technology. And at the forefront of this revolution? Swisstech Schreiner, a name synonymous with quality and innovation. Let's dive deep into how Swisstech Schreiner is harnessing the power of orbital welding to craft superior stainless steel piping systems for the beverage sector.

Why Stainless Steel Piping in the Beverage Sector?

Stainless steel, with its resistance to corrosion, durability, and non-reactivity, is the go-to choice for piping systems in the beverage industry. Maintaining hygiene, ensuring longevity, and delivering unadulterated products are crucial. Stainless steel, especially when seamlessly welded, fits this bill perfectly.

Swisstech Schreiner Orbital Welding Expertise

Precision at its Best: With orbital welding, Swisstech Schreiner guarantees precision. Every weld is consistent, ensuring that the stainless steel pipelines are free from vulnerabilities.

Accelerated Production: Swisstech Schreiner's advanced orbital welding equipment speeds up the production process. This efficiency means faster project completion and reduced downtimes.

Superior Hygiene Standards: In the beverage industry, cleanliness is paramount. Swisstech Schreiner's use of orbital welding ensures smooth and pore-free weld seams, eliminating crevices that can harbor contaminants.

Tailored Solutions: Understanding that every beverage producer might have unique requirements, Swisstech Schreiner offers customized stainless steel piping solutions, all harnessing the power of orbital welding.

The alliance of Swisstech Schreiner's expertise and the prowess of orbital welding technology signals a promising future for the beverage industry. As consumers become increasingly discerning about the quality and safety of their beverages, technologies and techniques that elevate these parameters will be in the limelight.

=> Read more : Swisstech Schreiner provides the solution for Stainless Steel Pipe Processing With Orbital Welding technology

The beverage industry's shift towards orbital welding is not just a fleeting trend but a testament to the sector's commitment to quality and innovation. And with industry leaders like Swisstech Schreiner championing this cause, one can only expect stainless steel piping systems of the highest caliber.

Swisstech Schreiner.

Add: ch 4153 reinach and hcm city vietnam

Hotline: (+84) 931 - 386 - 062

Phone: (+84) 931 - 386 - 062 +84931386062 ( zalo / viber / whatsapp )

Email: swiss.tech.schreiner@gmail.com

Other News

Various orbital welding machine applications

In an orbital welding machine, a process runs under computer control with very little intervention from the operator. This process is specifically used for repeatable welding and high-quality welding.

Công Nghệ Hàn Quỹ Đạo Orbital Cho Ống Inox Vi Sinh Và Công Nghiệp

Công nghệ hàn quỹ đạo hay còn gọi là hàn orbital, đây là công nghệ hàn được sử dụng rộng rãi, mang lại các mối hàn nhất quán, chất lượng cao và thượng được các nhà thầu thi công đường ống vi sinh sử dụng.

Beverage Industry Use Orbital Welding Technology Application

Because the requirements for the welding of microbiological stainless steel pipes for the food and beverage industry are very high, customers need to conduct a technology selection before welding the microbiological stainless steel pipes for their business.

Kiểm soát chất lượng và an toàn khi sử dụng hàn quỹ đạo

Bài viết này của Swisstech Schreiner nhằm mục đích cung cấp một cái nhìn sâu sắc về các nguyên tắc và phương pháp tốt nhất để đảm bảo kiểm soát chất lượng và an toàn tối ưu khi sử dụng máy hàn quỹ đạo Orbital welding machine.

Các cách tối ưu hóa công nghệ hàn quỹ đạo (Orbital welding technology)

Khám phá 5 cách tối ưu hóa khi áp dụng công nghệ hàn quỹ đạo Orbital welding technology, từ thiết lập tham số sẵn, kiểm tra hỗn hợp khí, xả khí chuẩn xác, đến bảo dưỡng định kỳ. Đảm bảo mối hàn đạt chuẩn với hướng dẫn chi tiết!

Why Choose Orbital Welding Technology?

The advent of orbital welding technology has changed the landscape of welding industries, from aerospace to orbital pharmaceutical and beyond. Let's explore orbital welding technology more deeply with Swisstech Schreiner through the following article