When one sips a refreshing soda or enjoys the aromatic depths of a wine, few consider the intricate journey that beverage has taken. Pipelines in the beverage industry play an important role. These conduits ensure consistent quality, seamless production, and the quality of the product. Leveraging advanced technologies and materials, these pipelines must resist corrosion, prevent contamination, and guarantee the ultimate taste experience for consumers. As Swisstech Schreiner works in the beverage industry, understanding these transport systems is key, reflecting the industry's commitment to excellence. Delve deep into the world of pipeline construction and savor the science behind your drink.

The Pipelines in the Beverage Industry

The beverage industry in Vietnam is a vast sector, incorporating everything from sodas to spirits and fruit juices to flavored waters. One essential aspect of the beverage industry that is often overlooked is the role of pipelines. These are not just pipes but crucial elements that ensure quality, safety, and efficiency in the beverage production process. This article will delve deep into the significance, design, and application of Construct pipelines in the beverage sector.

What are Pipelines in the Beverage Industry?

The pipelines are specialized pipes designed to transport liquid products or ingredients from one point to another within a beverage production facility. They're made from specific materials that ensure the liquid inside remains uncontaminated and retains its original taste and properties. Given the vast array of beverages produced, the pipelines can range from those used for water to those used for fruit concentrates, syrups, and alcoholic content.

The material used in the beverage industry is stainless steel pipe. Read more about stainless steel pipe processing at

The Importance of Constructing Pipelines

- Quality Assurance: The right pipeline ensures that the beverage maintains its flavor profile and stays free from contaminants. This directly impacts the end product's taste, texture, and aroma.

- Safety: With beverages, there's always a concern about bacterial growth or contamination. Pipelines in the beverage industry are designed to resist bacterial buildup, ensuring that the drink remains safe for consumption.

- Efficiency: They ensure a smooth flow of ingredients and finished products, speeding up production times and reducing waste.

Designing the Perfect Pipeline for the Beverage Industry

- Material Selection: The most common materials used for these pipelines are stainless steel and specific food-grade plastics. Stainless steel is resistant to corrosion, easy to clean, and can maintain the beverage's temperature.

- Seamless Construction: Joints or seams can be potential contamination points. The best pipelines are those with minimal joints, reducing the risk of bacterial buildup.

- Easy Maintenance and Cleaning: Pipelines need regular cleaning to maintain product quality. An effective design will allow for easy cleaning and maintenance without disrupting the production process.

- Flexibility: Given the dynamic nature of the beverage company, where new products are frequently introduced, the pipelines should be flexible enough to handle different liquids.

Application of pipeline construction in the Beverage Industry

- Soft Drinks: Pipelines transport carbonated water, flavorings, and sweeteners to mixing vats.

- Juices: They move fruit concentrates and purees, ensuring consistency in every bottle or carton.

- Alcoholic Beverages: Pipelines are used in distilleries to transfer spirits between various stages of production.

- Dairies: For products like flavored milk or yogurt drinks, pipelines ensure a seamless flow of milk, flavors, and other ingredients.

Pipeline construction is the unsung hero of the beverage industry. They play a pivotal role in maintaining the quality, safety, and efficiency of the production process. When investing in a beverage production facility, understanding and investing in the right kind of pipelines is crucial for the business's long-term success.

=> Read more about the peplines in beverage industry :

=> Pipeline Construction for Beverage Industry - Thi công hệ thống đường ống cho ngành nước giải khát

Constructing Pipelines by Orbital Welding Machine in the Beverage Industry

The F&B industry in Vietnam (Food and beverage industry), known for its diverse range of products, from refreshing sodas to elegant wines, places immense emphasis on quality, purity, and consistency. At the heart of this emphasis lies the robust infrastructure of constructed pipelines, essential for transferring liquids seamlessly. To ensure these pipelines are at their peak performance, a technique called orbital welding technology is deployed. Let's explore the synergy of constructing pipelines with the orbital welding machine in the beverage industry.

What is pipeline construction?

Pipelines are specialized conduits designed for the transportation of liquids, particularly in the beverage manufacturing process. Their primary objective is to transfer ingredients and finished products without contamination, preserving the beverage's intrinsic taste, quality, and safety.

The Role of Orbital Welding Machines

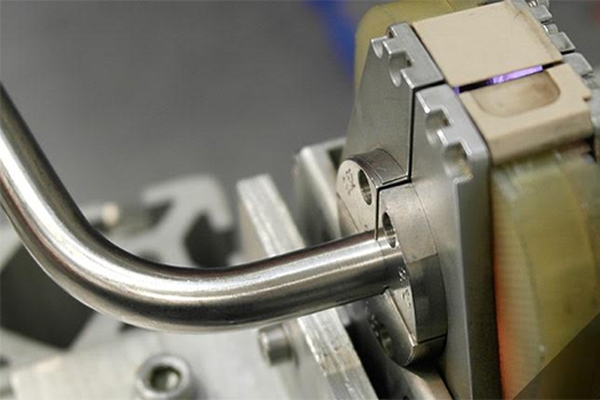

Orbital welding, an automated welding technique, uses specially designed equipment to rotate a welding arc from a tungsten electrode around a workpiece, typically a tube or pipe. Here's why it plays an important role in the beverage industry:

- Precision and Consistency: Manual welding might not always ensure uniformity, especially around pipes. Orbital welding, being automated, guarantees a consistent and high-quality weld every time, which is essential for the Food and beverage industry in Vietnam 2023, where quality can't be compromised.

- Hygiene and Purity: The beverage industry demands extreme hygiene standards. Orbital welding ensures minimal human interference, leading to cleaner welds and reducing the chances of contamination.

- Efficiency: Speed is of the essence in large-scale manufacturing. Orbital welding machine significantly reduces welding time, ensuring rapid assembly of construction pipelines.

Why Combine Pipeline Construction with Orbital Welding in the beverage industry?

- Seamless Flow: With orbital welding, the pipelines have smoother joints, ensuring that the liquids flow without obstructions. This is particularly vital for beverages, where even a minor obstruction can affect the final product's quality.

- Durability: Orbital welding enhances the strength of the joints, ensuring the pipelines last longer, even with constant use.

- Cost Efficiency: While the initial investment might be higher, the long-term benefits of reduced maintenance, increased pipeline longevity, and reduced product waste mean a better return on investment.

- Flexibility: As the beverage industry evolves, production lines might need modifications. Pipelines connected with orbital welding can be easily reconfigured without compromising on quality.

=> Read more about the Pipeline Construction in beverage industry at :

=> Orbital welding technology in the Pipeline Construction in beverage industry

In Conclusion

In the competitive landscape of the beverage industry, the amalgamation of Construct pipelines with the precision of orbital welding machines is a testament to the industry's commitment to quality, safety, and efficiency. As consumer demand rises and quality standards become even stricter, relying on advanced technologies like orbital welding will be the key for manufacturers to stay ahead. Contact Swisstech Schreriner if your business needs pipeline construction in beverage, pharmaceutical, biological, or chemical industries, solutions to hire or invest in orbital welding machines, solutions to maintain welding in the factory, etc. We will support you 24/7.

Swisstech Schreiner.

Add: ch 4153 reinach and hcm city vietnam

Hotline: (+84) 931 - 386 - 062

Phone: (+84) 931 - 386 - 062 +84931386062 ( zalo / viber / whatsapp )

Email: swiss.tech.schreiner@gmail.com

Other News

Quy Trình Gia Công Hàn Quỹ Đạo Ống Thép Không Gỉ

Quy trình gia công hàn quỹ đạo ống thép không gỉ – Stainless steel pipe processing cần đảm bảo hoàn thành đúng quy trình, an toàn và độ đồng nhất giữa các mối hàn sau khi hoàn thiện quy trình.

Vai trò của công việc bảo trì (Maintenance work) trong ngành công nghiệp giải khát

Các công ty sản xuất đồ uống luôn tìm cách để tăng năng suất và chất lượng sản phẩm. Điều này đòi hỏi các công việc bảo trì (Maintenance work) được thực hiện đúng cách để đảm bảo hoạt động liên tục của các thiết bị và máy móc trong quá trình sản xuất. Hãy cùng Swisstech tìm hiểu về vai trò của công việc bảo trì trong ngành công nghiệp giải khát.

Quy trình gia công ống thép không gỉ (Stainless steel pipe processing) cụ thể và chi tiết

Ống thép không gỉ hiện nay được ưa chuộng sử dụng rộng rãi trong các ngành công nghiệp khác nhau. Quy trình gia công ống thép không gỉ (Stainless steel pipe processing) bao gồm một số bước để đảm bảo sản phẩm chất lượng cao. Dưới đây Swisstech Schreiner xin giới thiệu các bước chính trong quy trình gia công ống thép không gỉ (Stainless steel pipe processing).

Vì sao nên gia công ống thép không gỉ (Stainless steel pipe processing) bằng máy hàn quỹ đạo?

Tại sao nên sử dụng máy hàn quỹ đạo trong quá trình gia công thép không gỉ (Stainless steel pipe processing)? Hãy cùng Swisstech Schreiner tìm hiểu gia công thép không gỉ là gì? Máy hàn quỹ đạo là gì? Và những lợi ích khi gia công thép không gỉ bằng máy hàn quỹ đạo tại ở bài viết sau nhé.

Giới thiệu 2 loại gia công ống thép không gỉ (stainless steel pipe processing)

Trình bày hướng dẫn gia công ống thép không gỉ đảm bảo các yếu tố chính xác, tiết kiệm chi phí và nâng cao chất lượng, giúp đảm bảo độ bền, tính thẩm mỹ và hiệu suất tối ưu. Cùng Swisstech Schreiner tìm hiểu quy trình gia công ống thép không gỉ hiệu quả, đáp ứng mọi yêu cầu kỹ thuật.

Công Nghệ Hàn Quỹ Đạo Orbital Trong Ngành Xử Lý Nước RO

Công nghệ hàn quỹ đạo Orbital đóng vai trò quan trọng trong ngành xử lý nước RO (Reverse Osmosis - Thẩm thấu ngược), ngành có yêu cầu ca về độ chính xác, độ bền và an toàn vệ sinh hệ thống ống dẫn.