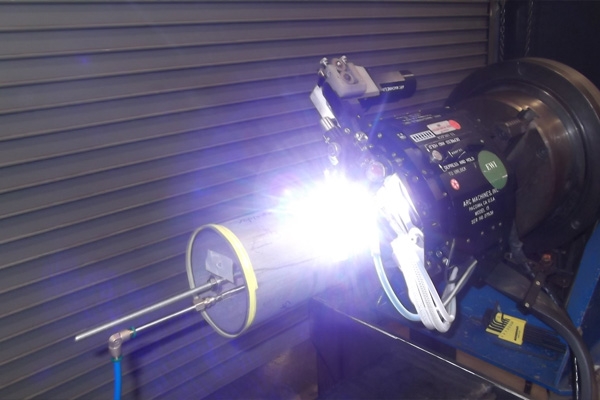

Orbital welding machines are the backbone of many industries, ensuring the structural integrity and durability of countless products. To maximize their lifespan and maintain optimal performance, regular maintenance is essential. In this article, we'll explore the reasons for regular maintenance of automatic welding machines and provide practical tips on how to properly care for them. At SwissTech Schreiner, we offer top-notch maintenance work welding services to keep your machines in peak condition for a lifetime of reliable performance.

Reasons for Regular Maintenance of Automatic Welding Machines

Automatic welding machines are a significant investment for any manufacturing operation. Ensuring their longevity and efficiency is crucial for a seamless production process. Here are some compelling reasons why regular maintenance work welding is imperative:

Safety First: The safety of your operators and the workplace is paramount. Regular maintenance helps identify and rectify potential safety hazards, ensuring a secure working environment.

Cost Savings: Preventive maintenance is more cost-effective than addressing breakdowns. Minor repairs and adjustments during scheduled maintenance can prevent major malfunctions that require costly repairs or replacements.

Optimal Performance: Well-maintained orbital welding machines deliver consistent and high-quality welds, reducing the chances of product defects and rework. This, in turn, boosts productivity and saves time.

Extended Lifespan: Proper maintenance can significantly extend the lifespan of your automatic welding machine, providing a better return on investment.

=> Read more : The importance of Maintenance Work Welding

How to Properly Maintain an Automatic Welding Machine

Proper maintenance work welding is the linchpin of keeping your automatic welding machine in peak working condition. Ensuring its longevity and performance not only saves you money but also guarantees safer and more efficient welding operations. Here, we'll dive deeper into the key steps to maintain your orbital welding machine effectively.

Check Safety

Safety is paramount when it comes to welding operations. Regular safety checks are vital to protect your operators and the workplace. Here are some critical aspects to consider:

Safety Features Inspection: Begin by examining all safety features and components. Ensure that emergency stop buttons are functional, protective shields are in place, and the ventilation system is operating correctly.

Operator Training: Make sure your operators are well-trained in safety procedures and equipment usage. They should be aware of potential hazards and how to mitigate them.

PPE Assessment: Check that all required personal protective equipment (PPE), such as helmets, gloves, and safety glasses, is readily available and in good condition.

Fire Safety: Verify the presence and functionality of fire extinguishers in the vicinity of the welding machine. Ensure that they are regularly inspected and maintained.

Check the Device Regularly

Routine inspections of the welding machine are essential to catch potential issues before they escalate. Here's what you should include in your regular maintenance work welding:

Visual Inspection: Start with a visual inspection of the entire orbital welding machine. Look for any signs of wear and tear, such as damaged cables, loose connectors, or corrosion.

Electrical Components: Pay close attention to the electrical components, including the power supply, control panel, and wiring. Any signs of overheating, exposed wires, or irregularities should be addressed promptly.

Moving Parts: Lubricate moving parts as recommended by the manufacturer to ensure smooth operation. Check for excessive friction or wear on components like drive rolls and feeders.

Cooling System: Inspect the cooling system, including fans and radiators, to prevent overheating. Ensure that air passages are clear of obstructions to maintain optimal cooling efficiency.

=> Read more : Bảo dưỡng thiết bị hàn (Maintenance of welding machine)

Check the Work Area

A well-maintained work area is essential for the overall integrity of your welding operations. Consider these factors when assessing your welding environment:

Cleanliness: Maintain a clean and organized work area. Regularly remove debris, dust, and welding residue from both the machine and the surrounding area to prevent contamination.

Ventilation: Proper ventilation is crucial to dissipate welding fumes and maintain good air quality. Ensure that exhaust systems and air filtration are functioning effectively.

Grounding: Inspect the grounding system to prevent electrical hazards. Proper grounding reduces the risk of electrical shocks and ensures the safety of your operators.

Clean the Welding Machine Regularly

Maintenance work welding on a regular basis is a simple yet effective way to prolong its lifespan and maintain peak performance. Here's how to go about it:

Exterior Cleaning: Remove dirt, dust, and welding residue from the machine's exterior using a soft brush, compressed air, or a damp cloth. Pay attention to events and openings.

Wire Feeders and Torches: Keep wire feeders and torches clean to prevent blockages or feeding issues. Regularly inspect and clean the contact tips for consistent weld quality.

Air Filters: If your orbital welding machine has air filters, clean or replace them as needed to maintain efficient airflow. Clogged filters can lead to overheating and reduced performance.

By following these detailed maintenance steps, you can ensure that your automatic welding machine remains safe, efficient, and reliable. Regular checks, a clean work area, and attention to safety measures are the keys to unlocking the full potential of your welding equipment, resulting in cost savings and better overall productivity.

=> Read more at : How important is maintenance work welding?

Maintenance Work Welding Services at Swiss Tech Schreiner

At SwissTech Schreiner, we understand the critical role that automatic welding machines play in your business. Our team of experienced technicians specializes in maintenance work welding services, ensuring that your equipment remains in optimal condition. With our expertise, you can trust that your orbital welding machines will achieve ultimate durability and a lifetime of reliable performance.

In conclusion, regular maintenance is the key to unlocking the full potential of your automatic welding machines. By prioritizing safety, routine checks, and proper cleaning, you can extend their lifespan, reduce operational costs, and enhance overall productivity. For expert maintenance work welding services, SwissTech Schreiner is your trusted partner in ensuring the longevity and durability of your welding equipment. Contact us today to schedule your maintenance work and experience the difference in performance and peace of mind.

Swisstech Schreiner.

Add: ch 4153 reinach and hcm city vietnam

Hotline: (+84) 931 - 386 - 062

Phone: (+84) 931 - 386 - 062 +84931386062 ( zalo / viber / whatsapp )

Email: swiss.tech.schreiner@gmail.com

Other News

Kỹ thuật ứng dụng công nghệ hàn quỹ đạo (orbital welding technology)

Trong công nghệ hàn quỹ đạo (orbital welding technology) , các yếu tố kỹ thuật đóng vai trò quyết định đến chất lượng mối hàn. Bài viết này của Swisstech Schreiner sẽ phân tích chi tiết từng yếu tố, bao gồm thông số hàn, loại điện cực, khí bảo vệ và kỹ thuật hàn.

Công Nghệ Hàn Quỹ Đạo Orbital Trong Ngành Xử Lý Nước RO

Công nghệ hàn quỹ đạo Orbital đóng vai trò quan trọng trong ngành xử lý nước RO (Reverse Osmosis - Thẩm thấu ngược), ngành có yêu cầu ca về độ chính xác, độ bền và an toàn vệ sinh hệ thống ống dẫn.

Orbital welding technology ‘s definition and history

New technologies require cleaner and more precise welds in industries such as the food and beverage industry, pharmaceutical industry. That is the reason why orbital welding technology appears and has become more popular in the world.

Công nghệ hàn quỹ đạo trong hệ thống dây chuyền sản xuất nhà máy bia

Công nghệ hàn quỹ đạo (orbital welding technology) đã trở thành một giải pháp đột phá, đặc biệt trong hệ thống dây chuyền sản xuất tại các nhà máy bia. Bài viết này của Swisstech Schreiner sẽ khám phá cách thức công nghệ hàn quỹ đạo đáp ứng ngành này.

Tầm Quan Trọng Của Bảo Dưỡng Máy Hàn

Bảo trì máy hàn quỹ đạo định kỳ giúp đảm bảo hiệu suất ổn định, kéo dài tuổi thọ thiết bị và ngăn ngừa sự cố. Tìm hiểu ngay lý do bảo trì là yếu tố không thể thiếu để tối ưu hóa chất lượng và an toàn trong sản xuất!

Công Nghệ Hàn Quỹ Đạo Orbital Cho Ống Inox Vi Sinh Và Công Nghiệp

Công nghệ hàn quỹ đạo hay còn gọi là hàn orbital, đây là công nghệ hàn được sử dụng rộng rãi, mang lại các mối hàn nhất quán, chất lượng cao và thượng được các nhà thầu thi công đường ống vi sinh sử dụng.