In the ever-evolving landscape of the manufacturing industry, the rise of orbital welding machines has marked a revolutionary change. Imagine a world where precision is not just a requirement but a norm, and efficiency is the key to success. But what exactly are these machines, and how do they stand out in the crowded field of manufacturing tools? Join Swisstech Schreiner to dive into the fascinating world of orbital welding machines, the automated marvels of the welding world.

What is an Orbital Welding Machine?

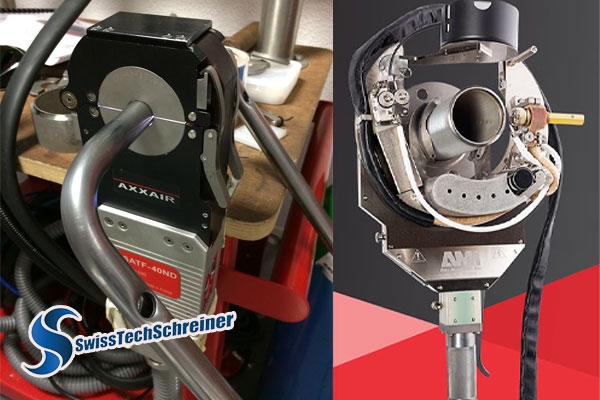

An orbital welding machine is not just any welding tool; it's a symbol of technological advancement in the field of welding. It's an automated welding system designed to deliver unparalleled precision and consistency. Unlike traditional welding methods, which rely heavily on the skill and steadiness of human welders, an orbital welding machine automates the process, ensuring each weld is as perfect as the last.

The Key Benefits of Using an Orbital Welding Machine in Industrial Applications

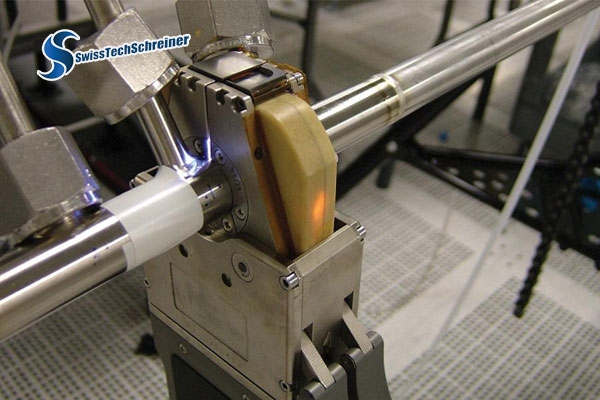

In the world of industrial welding, the rise of orbital welding machines marks a significant advancement. These machines bring several key benefits that revolutionize the way we approach welding tasks. Firstly, orbital welding excels in automation, setting it apart from manual methods. This automation translates into consistent and high-quality welds every time, reducing the variability and human error associated with traditional welding.

Moreover, these machines significantly boost productivity. With their automated processes, orbital welders can operate continuously, often requiring less oversight than manual welding. This efficiency is very important, especially in large-scale industrial projects where time is a critical factor.

Exploring the Various Applications of Orbital Welding Machines in Different Industries

Orbital welding machines have found a niche in various industries, each with unique requirements and challenges. In the aerospace industry, the precision and reliability of orbital welding are crucial for ensuring the safety and durability of aircraft components. Similarly, in the pharmaceutical industry, the high standards for cleanliness and contamination control make the precise, clean welds of orbital welding indispensable.

The food and beverage industry also benefits greatly from orbital welding. Here, the integrity of welds is essential to prevent bacterial growth and contamination in processing equipment. The versatility of orbital welding machines allows them to adapt to different materials and specifications across these industries, proving their broad applicability.

How to Choose the Right Orbital Welding Machine for Your Specific Needs

Selecting the right orbital welding machine can be daunting, but it’s vital for achieving the desired outcomes in your projects. When considering a purchase, focus on factors like the material types you'll be welding, the range of pipe sizes, and the specific environmental conditions of your worksite. It's also crucial to consider the welding machine's power requirements and portability, especially if the machine will be used in various locations.

Remember, the specifications of the welding machine should align closely with the demands of your project to ensure efficiency and quality.

=> See more articles on the same topic at :

=> Reasons why orbital welding machines are suitable for pipe welding

=> Choosing the right pipe welding method?- Orbital welding machine

=> Components and Features of an Orbital Welding Machine

Tips and Best Practices for Operating and Maintaining an Orbital Welding Machine

Effective operation and maintenance are key to maximizing the lifespan and performance of an orbital welding machine. Familiarize yourself with the operating procedures specific to your machine, and always adhere to safety guidelines. Regular maintenance, including cleaning and inspecting the welding heads and cables, is crucial.

Also, be proactive in troubleshooting common issues, such as inconsistencies in weld quality or mechanical failures. By staying vigilant and following these best practices, you can ensure that your orbital welding machine remains a reliable and valuable asset in your industrial toolkit.

Conclusion: Embracing the Efficiency and Precision of Orbital Welding Machines in Modern Manufacturing Processes

Orbital welding machines are more than just equipment; they are the future of welding in the manufacturing industry. By offering unmatched precision, efficiency, versatility, and safety, they stand as a testament to how technology can revolutionize an industry. As we continue to witness their growing applications and advancements, one thing is clear – the world of manufacturing is brighter and more innovative with orbital welding machines at its core.

Swisstech Schreiner.

Add: ch 4153 reinach and hcm city vietnam

Hotline: (+84) 931 - 386 - 062

Phone: (+84) 931 - 386 - 062 +84931386062 ( zalo / viber / whatsapp )

Email: swiss.tech.schreiner@gmail.com

Other News

Ứng dụng máy hàn quỹ đạo (orbital welding machine) vào các ngành công nghiệp

Phương pháp hàn quỹ đạo đã cho thấy hiệu quả cao trong việc nối các ống thép không gỉ cho các hệ thống mà các chất lỏng và sản phẩm phải được bảo vệ trong các điều kiện sạch sẽ hoặc tiệt trùng khi chảy qua đường ống. Với khả năng tạo ra các mối hàn đẹp mắt, ngấu chặt, không bị rạn và đảm bảo độ bền và đồng nhất cho hàng ngàn mối nối, hàn quỹ đạo đã trở thành máy hàn quỹ đạo (orbital welding machine) được ưa chuộng cho các ngành công nghiệp bán dẫn và sinh học dược phẩm tại Hoa Kỳ.

Orbital welding technology applied to industrial pipeline construction

With its unmatched accuracy and consistency, this cutting-edge tool has become indispensable for projects demanding the utmost quality. Let's learn about orbital welding technology with Swisstech Schreiner through the following article

Services related to Orbital Welding Machine

If you are considering purchasing an orbital welding machine or hire services related to orbital welding, there are several factors to consider to ensure that you make the right investment. Swiss Tech Schreiner will discuss everything you need to know about orbital welding machines in this blog.

Ứng dụng vật liệu inox và công nghệ hàn trong ngành nước giải khát

Trong sản xuất đồ uống hiện đại, beverage industry – công nghiệp đồ uống – đòi hỏi các dây chuyền sản xuất phải đạt tiêu chuẩn cao về vệ sinh, an toàn thực phẩm và độ bền của thiết bị. Hệ thống ống dẫn, bồn chứa và các mối hàn đóng vai trò then chốt.

Swisstech Schreiner provides the solution for Stainless Steel Pipe Processing With Orbital Welding technology

Join Swisstech Schreiner in embracing a new era of stainless steel pipe processing, where technology meets ingenuity. Swisstech Schreiner's dedication to innovation continues to reshape possibilities and elevate industry standards. Experience the future of welding – precise, efficient, and flawlessly connected.

Bảo dưỡng thiết bị hàn (Maintenance work of welding equipment)

Cho dù đó là thiết bị hàn khí, hồ quang hay điện trở, việc thực hiện các công tác bảo trì máy hàn (maintenance work of welding machine) có thể giúp chúng ta tiết kiệm được những chi phí lớn trong tương lai. Hãy cùng Swisstech Schreiner tìm hiểu quy trình và phương pháp bảo dưỡng (maintenance work) các loại máy hàn qua bài viết sau.