Orbital welding machines have revolutionized the pipe welding industry with their precision, efficiency, and unmatched consistency. In the following sections, we delve into the specifics of why orbital welding machines are the premier choice for professional pipe welding tasks. Join Swisstech Schreiner as we uncover the reasons behind the orbital welding technology growing prevalence and how they could be the key to unlocking new levels of excellence in pipe welding.

Precision and Consistency

Precision and Consistency are paramount in the world of pipe welding. Orbital welding machines offer a level of accuracy that is virtually unattainable with manual welding. These engineering utilize sophisticated computer programming to control the welding torch, allowing for precise weld penetration and consistent bead placement. This precision ensures that every weld is consistent with the last, significantly reducing the potential for defects and non-compliance with welding codes.

Enhanced Productivity

The enhanced productivity provided by orbital welding machine is a game-changer for the industry. When compared to manual welding, orbital welding technology is not just faster, but also more efficient. This is because the machine can work continuously without the need for breaks, and the welding parameters can be pre-set, reducing the setup time between welds. Case studies from various industries showcase a marked increase in output rates when switching to orbital welding. For instance, a pharmaceutical company reported a 60% reduction in welding time after implementing orbital systems, highlighting the profound impact on productivity.

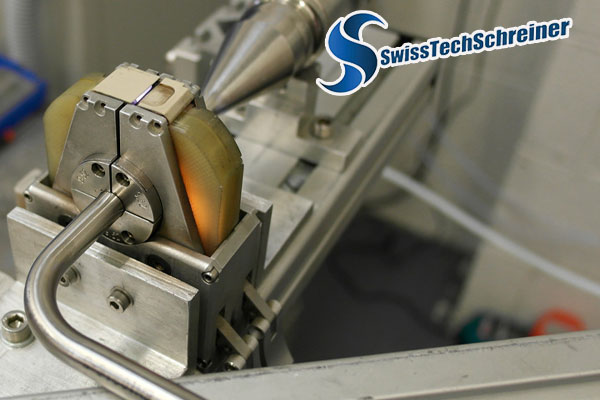

Superior Weld Quality

When it comes to Superior Weld Quality, orbital welding machines are in a league of their own. They operate in a controlled environment, which is critical in maintaining weld integrity. The closed chamber in which the weld is performed is shielded from external contaminants, significantly reducing the chances of weld contamination. This is particularly crucial in industries where purity and cleanliness are non-negotiable, such as in semiconductor or food processing plants or beverage industry.

Operator Safety

Operator Safety is significantly enhanced with orbital welding machines. Orbital welding technology is designed to take on the high-risk elements of welding, thereby reducing the risks associated with manual welding. With features that promote an ergonomic work environment, these machines help in minimizing operator fatigue and exposure to harmful welding fumes and intense light.

Versatility Across Materials and Environments

Versatility Across Materials and Environments is another feather in the cap for orbital welding machines. They are adept at handling a wide range of materials including stainless steel, titanium, and other exotic alloys. Additionally, orbital welding technology can operate effectively in various environmental conditions and in positions that would be challenging for a human welder, such as in confined spaces or overhead welding.

Cost-Effectiveness Over Time

The Cost-Effectiveness Over Time of using orbital welding machine systems becomes apparent when considering the long-term operational costs. These systems minimize material wastage and the need for rework due to their high-quality welds, translating into significant cost savings. Furthermore, the improved weld strength and durability mean less maintenance and longer lifespans for the welded structures.

Compliance with Industry Standards

Compliance with Industry Standards is critical, and orbital welding machines excel at ensuring adherence to these standards. They are designed to meet the stringent quality requirements set by industry regulators, making the certification and compliance process smoother and more reliable.

Advanced Data Recording and Traceability

Lastly, Advanced Data Recording and Traceability is an integral aspect of orbital welding technology. The ability to record detailed data about each weld helps in quality assurance and provides a traceable record for future reference. This data includes parameters such as weld heat input, time, and gas flow rates, which are essential for quality control and certification purposes.

=> See more articles on the same topic at :

=> (Orbital welding machine) Máy hàn quỹ đạo: giải pháp hiệu suất dành cho doanh nghiệp

=> TIG Orbital Welding Machine - Thiết bị hàn quỹ đạo TIG

=> Cách hoạt động máy hàn quỹ đạo (orbital welding machine) để hàn ống và đường ống

Orbital welding machines offer a multitude of benefits that are hard to overlook. From ensuring precision and consistency in each weld to enhancing productivity and ensuring operator safety, these machines are transforming pipe welding into a high-tech, efficient, and reliable process that meets the demands of modern industry. Their ability to weld a variety of materials in diverse conditions, coupled with their cost-effectiveness and compliance capabilities, positions orbital welding technology as a cornerstone technology in the fabrication industry.

The orbital welding technology caters to the increasing demands for quality and safety in sectors such as aerospace, pharmaceuticals, and semiconductor manufacturing, where perfect welds are not just desired but essential. The suitability of orbital welding systems for pipe welding is grounded in their ability to automate the welding process, minimizing human error and ensuring a higher standard of weld integrity.

From their advanced control systems that guarantee repeatable results to their adaptability to various materials and environments, these machines represent the pinnacle of welding technology. Contact Swisstech Schreiner if you need advice and support on any issues related to purchasing, selling, investing in orbital welding machine systems, applying orbital welding technology in pipeline construction, training, and maintenance. maintenance,... at the following contact information.

Swisstech Schreiner.

Add: ch 4153 reinach and hcm city vietnam

Hotline: (+84) 931 - 386 - 062

Phone: (+84) 931 - 386 - 062 +84931386062 ( zalo / viber / whatsapp )

Email: swiss.tech.schreiner@gmail.com

Other News

Công nghệ hàn quỹ đạo trong hệ thống dây chuyền sản xuất nhà máy bia

Công nghệ hàn quỹ đạo (orbital welding technology) đã trở thành một giải pháp đột phá, đặc biệt trong hệ thống dây chuyền sản xuất tại các nhà máy bia. Bài viết này của Swisstech Schreiner sẽ khám phá cách thức công nghệ hàn quỹ đạo đáp ứng ngành này.

Orbital Welding Technology Process - Hiểu về quy trình hàn quỹ đạo

Swisstech Schreiner có nhiều năm kinh nghiệm trong việc tạo ra các giải pháp hàn quỹ đạo phù hợp với nhu cầu hàn của khách hàng. Để tìm hiểu về quy trình áp dụng công nghệ hàn quỹ đạo (Orbital Welding Technology) và phát triển quy trình hàn quỹ đạo tùy chỉnh, hãy liên hệ với chúng tôi để được tư vấn và hỗ trợ.

Máy Hàn Quỹ Đạo: Giải Pháp Hàn Tối Ưu Cho Hệ Thống Đường Ống Chất Lượng Cao

Khám phá công nghệ hàn quỹ đạo tiên tiến với Swisstech Schreiner, giải pháp hàn tối ưu cho hệ thống đường ống đạt chuẩn. Tìm hiểu ứng dụng, lợi ích của máy hàn quỹ đạo Orbital welding machine trong công nghiệp.

Comparing Orbital Welding Machine and Traditional Welding Methods

Explore with Swisstech Schreiner the efficiency of orbital welding machines versus traditional welding methods. Learn the advantages of orbital welding technology compare it to conventional welding techniques. Stay informed to make decisions for your welding projects.

Giới thiệu công nghệ hàn quỹ đạo - Orbital welding technology

Công nghệ hàn quỹ đạo (orbital welding technology) ngày càng phổ biến vì nhiều công ty thực phẩm, đồ uống và dược phẩm. Hãy cùng Swisstech Schreiner tìm hiểu kỹ hơn về công nghệ này qua bài viết sau.

Các cách tối ưu hóa công nghệ hàn quỹ đạo (Orbital welding technology)

Khám phá 5 cách tối ưu hóa khi áp dụng công nghệ hàn quỹ đạo Orbital welding technology, từ thiết lập tham số sẵn, kiểm tra hỗn hợp khí, xả khí chuẩn xác, đến bảo dưỡng định kỳ. Đảm bảo mối hàn đạt chuẩn với hướng dẫn chi tiết!