In the bustling world of industry and machinery, the phrase "time is money" rings especially true. While innovation and automation have revolutionized the way we operate, the importance of maintenance work services remains at the very core of operational success. Let's Swisstech Schreiner delve into why maintaining your assets is not just essential, but pivotal for long-term sustainability and efficiency.

The Significance of Maintenance Work Services

As industries evolve and machinery becomes more sophisticated, the need for expert maintenance becomes even more paramount. It's a realm where prevention is not only better than cure; it's essential for survival.

1. Maximizing Operational Efficiency

Every machinery has an optimal operating point, a sweet spot where it functions at its best. Regular maintenance ensures that equipment consistently operates near or at this point, guaranteeing maximum efficiency and output. By preventing wear and tear, maintenance services ensure that operations continue smoothly and efficiently.

2. Extending Equipment Lifespan

Investments in machinery and equipment are substantial. Maintenance work services help protect these investments by prolonging the lifespan of each machine. Regular upkeep prevents premature aging, saving businesses from frequent and costly replacements.

3. Preventing Costly Downtime

Unplanned downtimes can be a nightmare for industries. They lead to missed deadlines, increased operational costs, and potential loss of clientele. With proactive maintenance services, potential issues are identified and rectified early, keeping the wheels of production continuously turning.

4. Ensuring Worker Safety

A well-maintained machine is a safe machine. By keeping equipment in optimal condition, maintenance services play a crucial role in preventing workplace accidents caused by machinery malfunctions. This not only protects workers but also saves businesses from potential legal liabilities.

5. Enhancing Product Quality

Machinery in top condition produces top-quality products. Maintenance ensures that equipment functions precisely as intended, ensuring consistency in production quality. In sectors where precision is key, regular upkeep is non-negotiable.

6. Conserving Resources

By ensuring that machinery runs efficiently, maintenance work services help industries save on resources. This includes electricity, raw materials, and man-hours. Over time, these savings can be substantial, contributing to the bottom line.

7. Upholding Brand Reputation

Consistent quality output and adherence to delivery timelines bolster a brand's reputation. Regular maintenance ensures that machinery is always ready to deliver, helping businesses maintain their market standing and customer trust.

Maintenance work services stand out as an important role for the industrial sector. They work silently in the background, ensuring that the limelight remains on production, innovation, and growth. In an age where competition is fierce and margins are slim, the importance of maintenance cannot be stressed enough

Remember, in the intricate process of production and progress, maintenance ensures the rhythm never falters.

=> Read more at : Maintenance work for the factory, why they need it

Swisstech Schreiner Maintenance Work Services: Keeping Industries Running Smoothly

In the world of manufacturing and industry, consistent uptime and operational efficiency are not just buzzwords – they are vital components of daily operations. The ability to maintain and promptly fix machinery is an art that Swisstech Maintenance Work Services has perfected over the years. Providing a comprehensive suite of maintenance solutions, Swisstech ensures that factories and industrial setups run optimally without the hiccups of unexpected downtimes.

Factory Maintenance Services

Industrial operations rely heavily on the impeccable functioning of equipment. At Swisstech Schreiner , the Factory Maintenance Services span a broad spectrum, ensuring that every cog, every screw, and every machine is up to mark. With seasoned professionals in their fold, Swisstech delivers reliable solutions, ensuring that businesses don't lose precious hours due to machinery malfunctions.

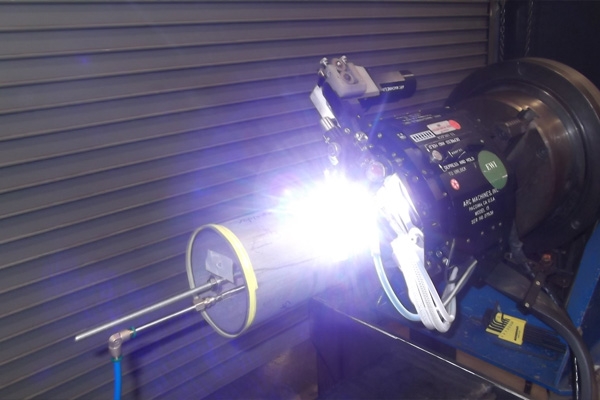

Maintenance work Welding

Welding is the backbone of many manufacturing processes, making its upkeep essential. Swisstech's maintenance work welding services encompass everything from equipment inspection to upkeep of welding tools. With meticulous attention to detail, Swisstech guarantees that welding processes remain unhindered, ensuring the strength and durability of the end products.

Machinery and Equipment Maintenance

Every piece of machinery, regardless of its size, plays a crucial role in the overall production line. Swisstech Schreiner understands this and offers specialized machinery and equipment maintenance services. By ensuring that machines are serviced, lubricated, and aligned correctly, Swisstech promises consistent output and prolonged equipment life.

Periodic Maintenance

Like the old adage goes, prevention is better than cure. With Swisstech's periodic maintenance services, businesses can proactively prevent potential breakdowns. By scheduling regular check-ups and service intervals, equipment health is monitored, and potential issues are rectified before they escalate, ensuring that operations continue to flow seamlessly.

Maintenance as Required

In the fast-paced world of industry, sometimes the unexpected occurs. In such scenarios, Swisstech is at the ready with its 'Maintenance as Required' services. Whether it's an unforeseen breakdown or a piece of machinery acting up, Swisstech's experts are on-call to address and resolve the issue promptly.

=> Read more : How important is maintenance work welding?

Why Choose Swisstech?

Swisstech Schreiner Maintenance Work Services isn't just another name in the industry; it's a hallmark of quality and reliability. With years of experience, state-of-the-art tools, and a team of dedicated professionals, Swisstech stands out as the go-to choice for businesses seeking efficient, cost-effective, and comprehensive maintenance solutions.

In the world of production, every minute counts, and Swisstech ensures that those minutes are never wasted due to maintenance-related issues. Partner with Swisstech today and experience the difference of unparalleled Maintenance Work service and unwavering commitment to excellence.

Boost your productivity with Swisstech Schreiner Maintenance Work Services – because a well-maintained factory is a productive one.

Swisstech Schreiner.

Add: ch 4153 reinach and hcm city vietnam

Hotline: (+84) 931 - 386 - 062

Phone: (+84) 931 - 386 - 062 +84931386062 ( zalo / viber / whatsapp )

Email: swiss.tech.schreiner@gmail.com

Other News

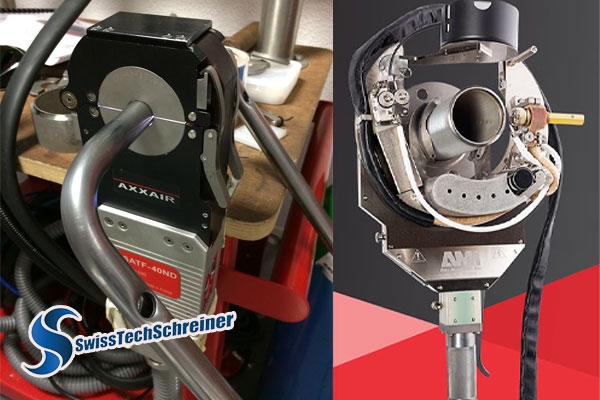

Công nghệ hàn quỹ đạo (Orbital welding technology) Giải pháp tối ưu cho ngành công nghiệp

Trong thời đại công nghiệp 4.0, việc cải tiến và nâng cao chất lượng sản phẩm là một yếu tố then chốt để doanh nghiệp có thể cạnh tranh và phát triển. Vì vậy, việc áp dụng công nghệ hàn quỹ đạo (Orbital welding technology) là một giải pháp tối ưu cho ngành công nghiệp hiện nay. Hãy cùng Swisstech Schreiner tìm hiểu ở bài viết dưới đây nhé.

Maintenance work welding - Tầm quan trọng của việc bảo trì hàn

Thực hiện tốt các công tác bảo trì, bảo dưỡng hàn (Maintenance work welding) định kỳ cho phép hệ thống máy hàn và cả hệ thống sản xuất hoạt động đáng tin cậy và an toàn trong thời gian dài. Nếu bảo trì không đúng cách, không đầy đủ hoặc hoàn toàn bị bỏ quên có thể dẫn đến hỏng hóc và dẫn đến các mối nguy hiểm nghiêm trọng bao gồm thương tích cho công nhân trong quá trình làm việc. Các công tác bảo trì ( Maintenance work) có thể thực hiện dễ dàng với một số kế hoạch cơ bản.

Orbital welding technology ‘s definition and history

New technologies require cleaner and more precise welds in industries such as the food and beverage industry, pharmaceutical industry. That is the reason why orbital welding technology appears and has become more popular in the world.

Tiêu Chuẩn Nghiêm Ngặt Khi Hàn Quỷ Đạo Trong Ngành Đồ Uống

Hàn quỹ đạo đóng vai trò quan trọng trong việc bảo vệ chất lượng sản phẩm, an toàn cho người tiêu dùng. Quy trình hàn quỹ đạo trong ngành đồ uống - beverage industry cần có độ chính xác cao, kỹ thuật cao và tuân thủ nghiêm ngặt các quy định về an toàn và vệ sinh thực phẩm.

Orbital welding technology applied to industrial pipeline construction

With its unmatched accuracy and consistency, this cutting-edge tool has become indispensable for projects demanding the utmost quality. Let's learn about orbital welding technology with Swisstech Schreiner through the following article

Maintenance Work Welding for Ultimate Durability and Lifetime

In this article, we'll explore the reasons for regular maintenance of orbital welding machines and provide practical tips on how to properly care for them. At SwissTech Schreiner, we offer top-notch maintenance work welding services to keep your machines in peak condition and reliable performance.