In the meticulous and highly regulated world of bioprocessing, ensuring the integrity, cleanliness, and efficiency of piping systems is paramount. Orbital welding technology has emerged as a frontrunner in facilitating these stringent requirements, providing precision, repeatability, and a superior level of cleanliness necessary for bioprocess piping applications. As industries continually evolve and adopt advanced technologies, it becomes crucial to delve into the considerations that make orbital welding an indispensable tool in this domain.

This comprehensive guide aims to unfold the myriad of aspects associated with orbital welding technology, catering specifically to bioprocess piping applications. Whether you are a seasoned professional in the bioprocessing industry, an engineering enthusiast, or someone looking to enhance their understanding of this pivotal technology, you’ve arrived at the right juncture.

We will explore the technical intricacies, benefits, and challenges associated with orbital welding, providing you with a holistic view of its application in bioprocess piping. The role of automation, precision, and consistency brought about by orbital welding stands as a testament to its indispensability, ensuring seamless operations and adherence to the highest standards of quality and safety.

Join Swisstech Schreiner as we delve into the world of orbital welding, uncovering its unparalleled advantages, exploring best practices, and addressing common challenges, ensuring that you are well-equipped to navigate the intricacies of this advanced welding technique in the realm of bioprocessing.

Orbital welding technology In BioProcess Piping Application

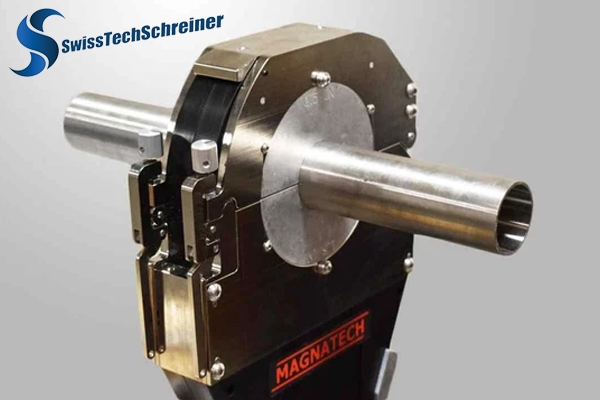

Orbital welding technology has proven to be a game changer in the field of bioprocess piping applications, offering precision, efficiency, and enhanced quality control. As industries continue to evolve and demand higher standards of purity and reliability, especially in the biopharmaceutical sector, the adoption of orbital welding has become almost indispensable. This technology stands out for its ability to produce consistent and repeatable welds, a critical factor when dealing with high-purity systems required in bioprocessing. The automated nature of orbital welding machine ensures that human error is minimized, resulting in welds that are not only accurate but also possess superior integrity and are free from contaminants.

In the highly regulated world of bioprocessing, the need for documentation and traceability is paramount. Orbital welding systems excel in this area, providing comprehensive data logging capabilities that record crucial welding parameters. This not only ensures compliance with industry standards but also facilitates easy validation of the welding process, instilling confidence in the final product's quality. The ability to store and retrieve welding data also plays a significant role in maintaining consistency across different batches of production, a key consideration for bio-manufacturers.

However, adopting orbital welding technology is not without its challenges. The initial investment cost for orbital welding machine can be significant, and there is a learning curve associated with mastering the technology. Furthermore, the success of orbital welding is heavily dependent on the proper preparation of the tubing and the correct setup of the welding parameters. This highlights the importance of having skilled technicians who are well-versed in the intricacies of orbital welding to ensure its successful implementation.

Orbital welding technology stands as a pillar of reliability, precision, and efficiency in bioprocess piping applications. Its ability to produce consistent, high-quality welds while adhering to stringent industry standards makes it an invaluable tool for bio-manufacturers. By embracing this technology, businesses not only enhance the integrity of their bioprocessing systems but also lay the foundation for continued innovation and excellence in the biopharmaceutical industry.

=> Read more at :

=> Orbital Welding Technology for Pipeline Systems Construction

=> Application of Orbital Welding Technology in the Construction of Industrial Pipeline Systems

=> The reason for using an Orbital Welding technology

Swisstech Schreiner Provide the Orbital Welding Technology Solutions

Swisstech Schreiner stands out as a prominent provider in the realm of Orbital Welding Technology, specifically tailored for Bioprocess Piping Applications, showcasing an unparalleled expertise and commitment to quality. By integrating cutting-edge technology and a deep understanding of the unique requirements in bioprocessing, Swisstech Schreiner ensures precision, efficiency, and the highest standards of cleanliness in every project undertaken. The complex and highly regulated nature of biopharmaceutical manufacturing demands nothing short of perfection, and that is where the services offered by Swisstech Schreiner truly shine.

In the intricate world of bioprocessing, the integration of Orbital Welding machine is not just a luxury but a necessity. Swisstech Schreiner’s team of highly skilled professionals brings to the table an extensive experience, ensuring that every weld is executed with the utmost precision and adheres to the strictest industry standards. The automated nature of orbital welding, championed by Swisstech Schreiner, minimizes the risk of human error, resulting in consistent, repeatable, and reliable welds that stand the test of time. This level of accuracy is paramount when dealing with the high-purity systems required in bioprocessing, and Swisstech Schreiner’s commitment to excellence ensures that this standard is met, time and time again.

Understanding the critical role of documentation and traceability in bioprocessing, Swisstech Schreiner ensures that every project is backed by comprehensive data logging capabilities. This commitment to transparency not only ensures compliance but also facilitates the validation process, instilling confidence in the end product. The ability to access and analyze welding data ensures consistency across different production batches, a vital consideration for bio-manufacturers aiming to maintain the highest levels of quality control.

Swisstech Schreiner’s proficiency in Orbital Welding Machine usage extends to handling complex piping configurations and tight spaces, ensuring that even the most intricate designs are accommodated without compromising on quality. This adaptability is a testament to their expertise and commitment to providing solutions that meet the unique demands of the bioprocessing industry. The initial investment in such advanced technology speaks volumes of Swisstech Schreiner’s dedication to leading the industry and setting standards.

Embracing the future of bioprocessing with open arms, Swisstech Schreiner provides more than just Orbital Welding Technology services; they offer peace of mind, consistency, and a guarantee of excellence. Their unwavering commitment to quality, precision, and adherence to industry standards makes them a trusted partner for bio-manufacturers around the globe. In Swisstech Schreiner, businesses find not just a service provider, but a partner dedicated to pushing the boundaries of what is possible in bioprocess piping applications, ensuring that they stay at the forefront of innovation and excellence in the biopharmaceutical sector.

Swisstech Schreiner.

Add: ch 4153 reinach and hcm city vietnam

Hotline: (+84) 931 - 386 - 062

Phone: (+84) 931 - 386 - 062 +84931386062 ( zalo / viber / whatsapp )

Email: swiss.tech.schreiner@gmail.com

Other News

Cách hoạt động máy hàn quỹ đạo (orbital welding machine) để hàn ống và đường ống

Máy hàn quỹ đạo (orbital welding machine) là một công cụ quan trọng trong ngành công nghiệp hàn. Với khả năng hàn tự động và chính xác cao, máy hàn quỹ đạo (orbital welding machine) đã trở thành sự lựa chọn hàng đầu cho việc hàn ống và đường ống trong các dự án xây dựng, cơ khí, và năng lượng. Bài viết sau của Swisstech Schreiner sẽ tìm hiểu cách hoạt động của máy hàn quỹ đạo (orbital welding machine) trong quá trình hàn ống và đường ống. Hãy cùng theo dõi nhé.

Dịch vụ bảo trì hàn (Maintenance work welding) chất lượng cao

Dịch vụ bảo trì hàn (Maintenance work welding) đóng vai trò thiết yếu trong việc đảm bảo tính bền vững và an toàn cho mọi công trình. SwissTech Schreiner luôn sẵn sàng đáp ứng mọi nhu cầu của bạn với cam kết về độ chính xác, độ bền, và sự an toàn tối đa.

Các lỗi mối hàn xấu và cách khắc phục nhanh chóng, hiệu quả

Khám phá các lỗi mối hàn xấu thường gặp và cách khắc phục nhanh chóng, hiệu quả. Đảm bảo chất lượng, độ bền khi gia công ống thép không gỉ Stainless steel pipe processing cho các công trình và an toàn trong sản xuất cùng Swisstech Schreiner.

Công Nghệ Hàn Quỹ Đạo Orbital Trong Ngành Xử Lý Nước RO

Công nghệ hàn quỹ đạo Orbital đóng vai trò quan trọng trong ngành xử lý nước RO (Reverse Osmosis - Thẩm thấu ngược), ngành có yêu cầu ca về độ chính xác, độ bền và an toàn vệ sinh hệ thống ống dẫn.

Stainless Steel Pipe Processing và Hàn Quỹ Đạo: Giải Pháp Gia Công Tối Ưu Cho Thép Không Gỉ 904L

Giải Pháp Gia Công Tối Ưu Cho Thép Không Gỉ 904L.Sự đầu tư bài bản vào quy trình gia công và công nghệ hàn chính là chìa khóa nâng cao năng lực sản xuất, giảm thiểu lỗi kỹ thuật và đảm bảo tuổi thọ vận hành lâu dài cho toàn hệ thống.

Máy hàn quỹ đạo là gì? Cấu tạo, nguyên lý và ứng dụng trong các ngành công nghiệp hiện đại

Trong sản xuất công nghiệp, đặc biệt là các lĩnh vực yêu cầu cao về độ sạch và độ chính xác như dược phẩm, thực phẩm, hóa chất và công nghệ sinh học, việc tạo ra các mối hàn chất lượng cao là điều tối quan trọng. Để đáp ứng yêu cầu này, công nghệ hàn quỹ đạo tự động đã ra đời và ngày càng khẳng định vai trò không thể thay thế