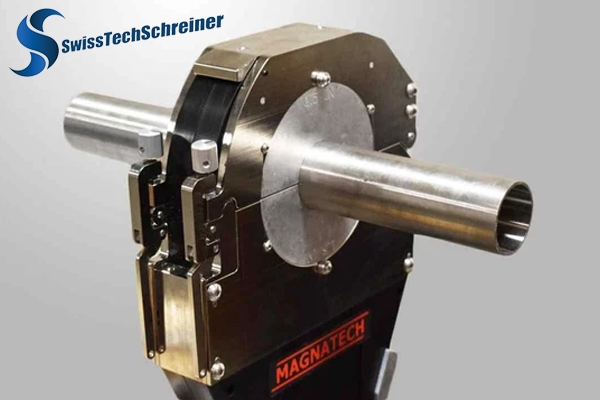

In the bustling realm of construction, efficiency and precision are more than just buzzwords—they're vital standards that can spell the difference between a project's success and failure. Enter orbital welding technology, a revolutionary advancement that's been quietly transforming the construction pipeline systems industry. At its core, orbital welding offers an automated approach to joining tubes and pipes in challenging environments, ensuring welds are consistently perfect, with minimal human error.

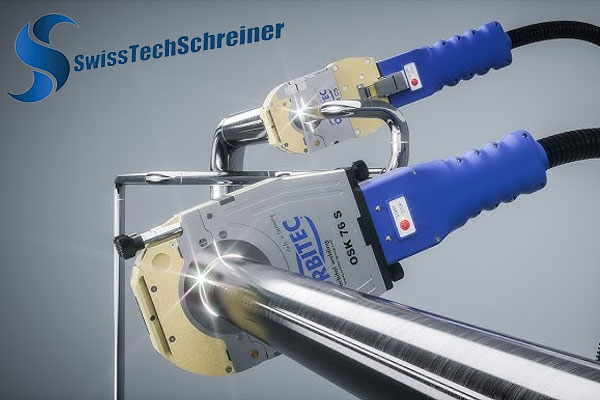

Imagine a scenario where the construction of intricate pipeline systems, which often span vast distances and navigate challenging terrains, can be expedited without compromising on the quality of welds. That’s precisely what orbital welding brings to the table. This technology employs computer-controlled systems that ensure weld consistency and accuracy. Traditional manual welding, while effective, is subject to human fatigue and variance. With orbital welding machine , every weld is completed with the same meticulous precision, whether it's the first or the hundredth.

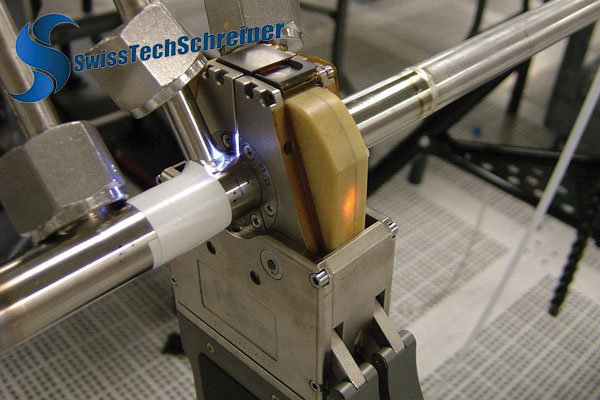

Moreover, orbital welding technology has proven to be a boon in environments where manual welding is virtually impossible or risky. Think about space-constrained areas, or projects where the pipeline materials demand precise temperature controls for optimum weld quality. In these contexts, orbital welding isn’t just an alternative—it’s an imperative.

The integration of orbital welding technology in construction pipeline systems is more than just a nod to modernization—it’s a commitment to excellence, speed, and safety. As construction projects grow more complex and the demand for faster completion times intensifies, embracing such innovative methodologies isn't just smart—it's essential. And for stakeholders aiming for a seamless fusion of speed and quality, orbital welding is undoubtedly the way forward.

Orbital Welding Technology for the Pipeline systems in pharmaceutical industry

In the fast-paced and highly regulated world of pharmaceutical manufacturing, precision and quality control are paramount. As the demand for pharmaceutical products continues to surge, so does the need for advanced manufacturing technologies. One such innovation that has transformed the industry is the introduction of Swisstech Schreiner orbital welding technology. These cutting-edge devices are making waves in the pharmaceutical sector, providing unmatched efficiency, precision, and reliability in welding applications. In this article, we delve into how Swisstech Schreiner orbital welding machines are becoming the go-to solution for the pharmaceutical industry.

The Precision Revolution:

Pharmaceutical manufacturing processes demand the highest level of precision and quality assurance. Even the smallest deviation in welding can compromise the integrity of critical components, potentially affecting the safety and efficacy of medications. This is where Swisstech Schreiner orbital orbital welding technology shines. With their computer-controlled, automated welding processes, these machines ensure unparalleled precision and consistency, reducing the risk of human error to almost zero.

Enhancing Product Quality:

In the pharmaceutical industry, product quality is non-negotiable. Any compromise can lead to costly recalls and damage to a company's reputation. Swisstech Schreiner orbital welding machine is engineered to meet the stringent quality standards of pharmaceutical manufacturing. They operate with exceptional cleanliness and sterility, making them ideal for welding applications in environments where contamination control is paramount. This ensures that pharmaceutical products are free from impurities and meet the highest quality standards.

Optimizing Efficiency:

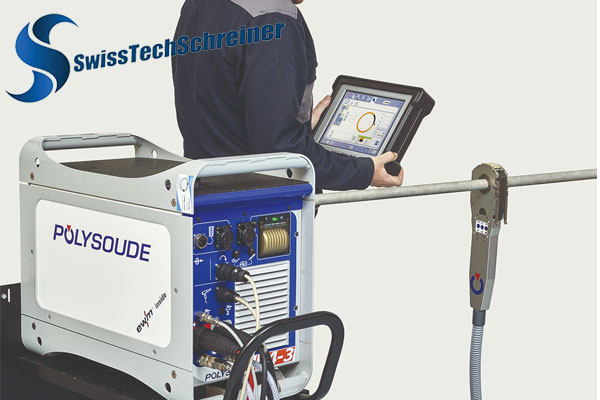

Time is of the essence in pharmaceutical manufacturing. Swisstech Schreiner orbital welding technology offers a significant advantage in terms of efficiency. Their automated welding process eliminates the need for manual labor, reducing production time and costs. Additionally, these machines require minimal setup and downtime, allowing manufacturers to maintain a consistent workflow and meet tight production schedules.

Cost Savings and Sustainability:

In an industry where cost control is vital, Swisstech Schreiner orbital welding machines are a cost-effective solution. They minimize material wastage and energy consumption compared to traditional welding methods. Moreover, the precision of orbital welding reduces the need for costly rework, further lowering production costs. In an era where sustainability is a top concern, these machines also contribute to reducing the carbon footprint of pharmaceutical manufacturing.

Compliance and Documentation:

Regulatory compliance is a constant challenge in the pharmaceutical sector. Swisstech Schreiner orbital welding technology comes equipped with advanced data logging and reporting features. This ensures that all welding processes are well-documented and meet the stringent requirements of regulatory authorities. With comprehensive documentation readily available, pharmaceutical manufacturers can navigate the regulatory landscape with confidence.

Training and Support:

Implementing orbital welding technology in a highly regulated industry requires skilled personnel. Swisstech Schreiner understands this need and provides comprehensive training and support to its customers. Their expert technicians offer training programs to ensure that pharmaceutical manufacturers can make the most of their orbital welding machines, maximizing efficiency and precision.

The pharmaceutical industry demands the highest standards in quality, precision, and efficiency, and Swisstech Schreiner orbital welding machines are meeting these demands head-on. Advanced orbital welding technology, focus on compliance, and commitment to sustainability are reshaping pharmaceutical manufacturing. As pharmaceutical companies strive for excellence in their operations, Swisstech Schreiner orbital welding machines are proving to be indispensable tools, ensuring the continued production of safe and high-quality medications for the world. Embracing this technology is not just a choice; it's a necessity for the future of pharmaceutical manufacturing.

Swisstech Schreiner.

Add: ch 4153 reinach and hcm city vietnam

Hotline: (+84) 931 - 386 - 062

Phone: (+84) 931 - 386 - 062 +84931386062 ( zalo / viber / whatsapp )

Email: swiss.tech.schreiner@gmail.com

Other News

Những điều doanh nghiệp cần biết trước khi sử dụng Công nghệ hàn quỹ đạo Orbital welding technology

Khám phá cơ chế hoạt động, các ưu điểm và ứng dụng của hàn quỹ đạo trong công nghiệp. Tìm hiểu về thiết bị cần thiết, quy trình chuẩn bị và thương hiệu máy hàn hàng đầu. Đọc ngay bài viết của Swisstech Schreiner để hiểu rõ lợi ích và giải pháp hàn chất lượng cao

Mục đích và lợi ích của công việc bảo trì hàn(Maintenance work welding)

Công việc bảo trì hàn (Maintenance work welding) là công việc cần thiết và quan trọng để máy móc thiết bị luôn hoạt động tốt nhất. Có thể quý doanh nghiệp chưa biết máy móc nhanh giảm tuổi thọ chủ yếu là do không được bảo trì, bảo dưỡng thường xuyên. Tuy nhiên, không phải doanh nghiệp nào cũng có kế hoạch bảo trì máy móc đúng cách.

Cách hoạt động máy hàn quỹ đạo (orbital welding machine) để hàn ống và đường ống

Máy hàn quỹ đạo (orbital welding machine) là một công cụ quan trọng trong ngành công nghiệp hàn. Với khả năng hàn tự động và chính xác cao, máy hàn quỹ đạo (orbital welding machine) đã trở thành sự lựa chọn hàng đầu cho việc hàn ống và đường ống trong các dự án xây dựng, cơ khí, và năng lượng. Bài viết sau của Swisstech Schreiner sẽ tìm hiểu cách hoạt động của máy hàn quỹ đạo (orbital welding machine) trong quá trình hàn ống và đường ống. Hãy cùng theo dõi nhé.

Giải pháp Gia công ống thép không gỉ (Stainless steel pipe processing)

Hàn gia công ống thép không gỉ (Stainless steel pipe processing) là giải pháp tối ưu dành riêng cho các kết cấu công nghiệp. Dưới đây là một vài chia sẻ được tổng hợp bởi Swiss Tech Schreiner mà doanh nghiệp nên tham khảo về lĩnh vực này.

Tầm Quan Trọng Của Việc Bảo Trì Máy Hàn Maintenance work welding

Khám phá lịch trình bảo trì định kỳ cho máy hàn Maintenance work welding để đảm bảo hiệu suất tối ưu và an toàn cao nhất. Từ bảo trì hàng giờ đến hàng năm, hãy tìm hiểu cách giữ cho thiết bị của bạn hoạt động mượt mà. Liên hệ Swisstech Schreiner để biết thêm chi tiết và hỗ trợ

Maintenance work welding - Tầm quan trọng của việc bảo trì hàn

Thực hiện tốt các công tác bảo trì, bảo dưỡng hàn (Maintenance work welding) định kỳ cho phép hệ thống máy hàn và cả hệ thống sản xuất hoạt động đáng tin cậy và an toàn trong thời gian dài. Nếu bảo trì không đúng cách, không đầy đủ hoặc hoàn toàn bị bỏ quên có thể dẫn đến hỏng hóc và dẫn đến các mối nguy hiểm nghiêm trọng bao gồm thương tích cho công nhân trong quá trình làm việc. Các công tác bảo trì ( Maintenance work) có thể thực hiện dễ dàng với một số kế hoạch cơ bản.