In the dynamic world of the beverage industry, where quality, efficiency, and hygiene hold paramount importance, innovations in manufacturing and assembly processes play a critical role in upholding standards and driving success. One technological advancement that has significantly transformed the landscape of beverage production is orbital welding technology.

This method of welding has gained immense popularity and become a preferred choice for many beverage manufacturers, thanks to its unparalleled precision, consistency, and reliability. In this comprehensive guide, Swisstech Schreiner delves into the core reasons why the beverage industry is increasingly opting for orbital welding technology, highlighting its remarkable benefits and showcasing real-world applications that underscore its indispensability.

What is orbital welding technology in the beverage industry?

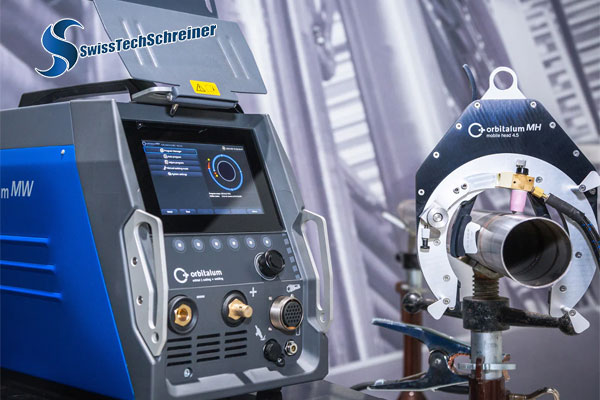

Orbital welding technology in the beverage industry represents a groundbreaking shift, offering unparalleled precision, consistency, and hygiene in the assembly and maintenance of piping systems. This advanced welding technique utilizes computer-controlled processes, ensuring that every weld is performed with exacting accuracy, a crucial factor in an industry where even the slightest contamination can lead to product spoilage and significant financial losses.

By automating the welding process, orbital welding minimizes human error, resulting in stronger, more reliable welds that stand up to the rigorous demands of beverage production. The technology is particularly beneficial for working with stainless steel tubing, a material commonly used in the industry due to its corrosion-resistant properties.

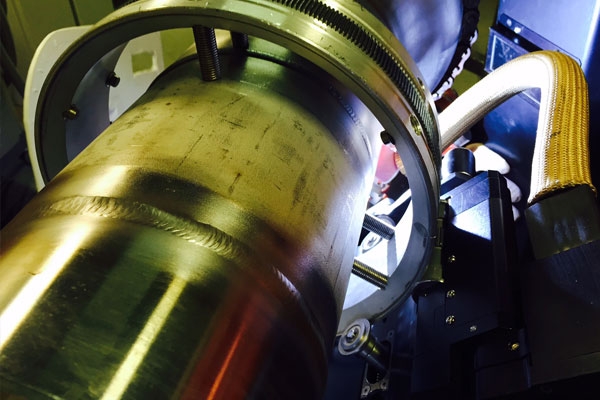

The seamless and crevice-free welds achieved with orbital welding technology are critical in preventing the accumulation of bacteria and ensuring the integrity of the product throughout the production cycle. Moreover, the speed and efficiency of orbital welding not only expedite project timelines but also contribute to cost savings, making it an economically sound choice for beverage manufacturers.

Additionally, the ability to replicate precise welds across numerous applications ensures uniformity and standardization, further enhancing the quality control measures within the industry. Orbital welding’s contribution to maintaining the pristine condition of the internal surfaces of tubing and pipes cannot be overstated, as it plays a direct role in ensuring that the final product meets the highest standards of quality and safety.

The reason why the beverage industry chooses orbital welding technology

The beverage industry’s inclination toward orbital welding technology stems from its relentless pursuit of excellence, precision, and hygiene, as these factors directly correlate with the quality and safety of the final product. Orbital welding technology, with its computer-controlled precision, guarantees impeccable welds, ensuring that the piping systems used in beverage production are secure, leak-proof, and free from contaminants.

The seamless welds created by this advanced method eliminate crevices that could harbor bacteria, thus maintaining the purity of the beverages and ensuring compliance with stringent health and safety standards. Furthermore, the consistency provided by orbital welding ensures uniformity across all welding operations, a critical aspect for large-scale manufacturers aiming to maintain product consistency across different batches and locations.

The industry’s adoption of this technology also aligns with its commitment to efficiency and cost-effectiveness. Orbital welding not only speeds up the assembly process but also reduces the need for post-weld cleanups and revisions, directly translating to time and cost savings.

The durability of the welds ensures longevity and reduces the need for frequent maintenance, providing long-term financial benefits. Moreover, the versatility of orbital welding makes it suitable for various applications within the beverage production process, from connecting process piping to assembling intricate components, making it a one-stop solution for diverse welding needs.

=> Read more at :

=> Considerations for Orbital Welding Technology in BioProcess Piping Application

=> Orbital Welding Technology for Pipeline Systems Construction

=> How to Use Orbital Welding Technology Properly: A Comprehensive Guide

Swisstech Schreiner provide the orbital welding technology solution for the business in the beverage industry

Swisstech Schreiner stands out as a pivotal player in revolutionizing the beverage industry, offering cutting-edge orbital welding technology solutions tailored to meet the unique demands of businesses within this sector. Their expertise in providing high-precision, reliable welding equipment ensures that manufacturers have access to the best tools necessary for maintaining the integrity, purity, and safety of their products. Swisstech Schreiner’s commitment to innovation is evident in their continual efforts to refine and enhance their orbital welding solutions, keeping pace with the evolving needs of the beverage industry.

The company’s holistic approach extends beyond just supplying equipment; they offer comprehensive support and training, ensuring that their clients can fully leverage the advantages of orbital welding technology. This commitment to customer success has positioned Swisstech Schreiner as a trusted partner for beverage manufacturers looking to optimize their production processes, reduce downtime, and maintain the highest standards of quality and safety. Their solutions are not just about facilitating seamless welds; they are about fostering operational excellence and driving industry advancements.

Swisstech Schreiner.

Add: ch 4153 reinach and hcm city vietnam

Hotline: (+84) 931 - 386 - 062

Phone: (+84) 931 - 386 - 062 +84931386062 ( zalo / viber / whatsapp )

Email: swiss.tech.schreiner@gmail.com

Other News

The stainless steel pipe processing

Swisstech Schreiner is always proud to be the leader in the field of stainless steel pipe processing with a team of experienced employees. We offer solutions about the stainless steel pipe processing for pipeline systems and services related to maintenance work and orbital welding technology.

Lợi ích của máy hàn quỹ đạo (orbital welding machine) so với máy hàn truyền thống

Máy hàn quỹ đạo (orbital welding machine) một giải pháp hiện đại, vượt trội so với các phương pháp hàn truyền thống nhờ vào khả năng cung cấp mối hàn chính xác, đồng đều, và chất lượng cao. Hãy cùng Swisstech Schreiner khám phá những lợi ích mà máy hàn orbital mang lại qua bài viết sau.

Construction of pipeline systems in the beverage industry

Let's Swisstech Schreiner discover the intricate process behind constructing efficient pipeline systems tailored for the dynamic demands of the beverage industry. Explore key techniques (orbital welding machine), and considerations for ensuring seamless liquid transport, hygiene, and quality.

Tăng sức bền cho công trình: Vai trò không thể thay thế của dịch vụ bảo trì hàn - Maintenance work

Các cấu trúc kim loại thường xuyên chịu ảnh hưởng từ tải trọng và điều kiện môi trường khắc nghiệt, khiến chúng dễ bị suy giảm độ bền, phát sinh hiện tượng rạn nứt, oxy hóa hoặc rò rỉ theo thời gian. Nếu không được kiểm tra và bảo trì kịp thời, các vấn đề này có thể gây ra hậu quả nghiêm trọng, ảnh hưởng đến an toàn lao động và vận hành thiết bị.

Ứng dụng máy hàn quỹ đạo (orbital welding machine) vào các ngành công nghiệp

Phương pháp hàn quỹ đạo đã cho thấy hiệu quả cao trong việc nối các ống thép không gỉ cho các hệ thống mà các chất lỏng và sản phẩm phải được bảo vệ trong các điều kiện sạch sẽ hoặc tiệt trùng khi chảy qua đường ống. Với khả năng tạo ra các mối hàn đẹp mắt, ngấu chặt, không bị rạn và đảm bảo độ bền và đồng nhất cho hàng ngàn mối nối, hàn quỹ đạo đã trở thành máy hàn quỹ đạo (orbital welding machine) được ưa chuộng cho các ngành công nghiệp bán dẫn và sinh học dược phẩm tại Hoa Kỳ.

Các biện pháp an toàn trong công tác bảo trì (Maintenance work)

Công tác bảo trì đóng vai trò quan trọng trong công việc hàn hiện đại. Tuy nhiên, công việc này cũng tiềm ẩn khá nhiều nguy hiểm cho người thợ. Hãy theo dõi bài viết dưới đây của Swisstech Schreiner để biết được các biện pháp an toàn cho công tác bảo trì (Maintenance work) hàn quỹ đạo này nhé.