Before embarking on the stainless steel pipe processing, it is crucial to undertake a series of preparatory steps to ensure the success and safety of the welding operation. These preliminary measures play a pivotal role in creating a conducive environment for effective welding and minimizing potential risks associated with the process. Join Swisstech Schreiner to learn about the steps taken in the process of welding and processing industrial steel pipes effectively.

Preparation steps before the stainless steel pipe processing

This inspection involves assessing the condition of the pipes for any defects, damages, or inconsistencies. Identifying and addressing these issues beforehand helps prevent complications during the orbital welding machine work process and ensures the integrity of the final weld. Additionally, it allows for the selection of appropriate welding techniques and materials based on the specific requirements of the pipes. Additionally, it allows for the selection of appropriate welding techniques and materials based on the specific requirements of the pipes.

Once the inspection is complete, thorough cleaning of the pipes before stainless steel pipe processing becomes the next essential step. The surfaces to be welded must be free from any contaminants such as rust, oil, grease, or other residues that can adversely affect the quality of the weld. Proper cleaning not only facilitates better weld penetration but also enhances the overall strength and durability of the welded joint. Various methods, including brushing, grinding, or chemical cleaning, may be employed depending on the nature and extent of the contaminants.

After cleaning, precise alignment of the pipes is critical for achieving accurate and uniform welds. Proper alignment ensures that the pipes are in the correct position, maintaining the desired angle and gap for welding. This step is particularly important in the case of pipe systems that require precise fitting and alignment to function effectively. This is also especially important in using orbital welding technology to weld industrial pipeline systems. The use of alignment tools, jigs, and fixtures aids in achieving the necessary accuracy and alignment before welding begins.

Once the pipes are aligned, consideration must be given to the selection and preparation of welding materials. This involves choosing the appropriate welding electrodes, filler metals, and shielding gases based on the type of pipe, welding process, and material specifications for the orbital welding machine. Ensuring that these materials meet the required standards and are in optimal condition contributes significantly to the success of the orbital welding operation.

In addition to these steps, it is essential to implement proper safety measures before commencing the welding for stainless steel pipe processing. This includes the use of personal protective equipment (PPE) such as welding helmets, gloves, and safety glasses. Adequate ventilation and fire prevention measures should also be in place to mitigate the potential hazards associated with welding.

=> Read more at :

=> Components and Features of an Orbital Welding Machine

=> Reasons why orbital welding machines are suitable for pipe welding

=> Pipe Welding Technique Using Orbital Welding Machine

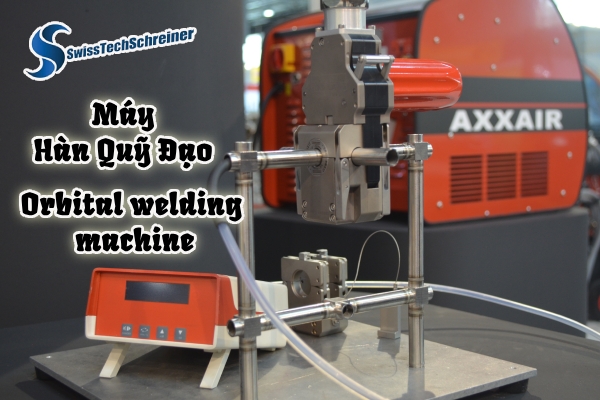

The stainless steel pipe processing by Orbital welding machine

.jpg)

Utilizing an Orbital welding machine in pipe welding has become popular in some particular industries due to its unmatched ability to ensure superior stability and quality of welds compared to conventional hand welding methods. The precise control offered by the Orbital welding machine over various parameters contributes significantly to achieving consistent and high-quality welding results.

One key advantage of using an Orbital welding machine is its continuous control of welding current intensity. This feature ensures a consistent welding process, vital for maintaining uniformity in the welds. The machine allows for welding on tubes with a thickness ranging from 0.5mm to 4mm, making it versatile and suitable for a wide range of pipe welding applications.

Another critical aspect controlled by the Orbital welding machine is the flow of shielding gas. Proper control ensures a sufficient amount of shielding gas, crucial for protecting the weld from atmospheric contamination. Balancing the pressure inside and outside the tube is vital to avoid defects such as concave or convex weld seams. If external pressure surpasses the internal pressure, the weld seam tends to be concave, whereas the opposite results in a convex weld seam.

Temperature control is a paramount consideration, particularly when dealing with stainless steel. The Orbital welding machine allows for precise temperature control, minimizing the risk of issues such as burning, oxidation, denaturation, and discoloration of the welded parts. This is particularly critical for maintaining the aesthetic and functional integrity of stainless steel components.

In the context of welding stainless steel pipe processing, the Orbital welding machine excels in producing straight, even, and aesthetically pleasing welds. This is essential for creating strong, leak-proof connections. Moreover, the machine's capability to weld two different types of materials evenly without deformation is a remarkable feature. This ensures that even when welding dissimilar metals, the Orbital welding machine delivers welds of exceptional quality and consistency.

In summary, the Orbital welding machine stands out as a necessity in pipe welding, offering precise control over welding parameters such as current intensity, shielding gas flow, and temperature. Its ability to produce straight, even, and aesthetically pleasing welds, even when dealing with different materials, underscores its significance in achieving high-quality and reliable welded joints.

In conclusion, Swisstech Schreiner stands as a reliable partner for businesses delving into the construction, installation, and stainless steel pipe processing, particularly in crucial industries requiring orbital welding machines. With a proven track record of excellence and a commitment to cutting-edge technology, Swisstech Schreiner is well-equipped to provide comprehensive support tailored to the unique needs of each client. Elevate your projects with the assurance of quality and efficiency by forging a partnership with Swisstech Schreiner today.

Swisstech Schreiner.

Add: ch 4153 reinach and hcm city vietnam

Hotline: (+84) 931 - 386 - 062

Phone: (+84) 931 - 386 - 062 +84931386062 ( zalo / viber / whatsapp )

Email: swiss.tech.schreiner@gmail.com

Other News

Cách ngăn ngừa lỗi thiếu nóng chảy để đảm bảo mối hàn chất lượng cao

Hàn quỹ đạo giúp tạo ra mối hàn chính xác, nhưng lỗi thiếu nóng chảy có thể gây nguy hiểm. Tìm hiểu nguyên nhân, cách khắc phục và giải pháp từ Swisstech Schreiner để đảm bảo mối hàn chất lượng cao!

Swisstech Schreiner and Construct Pipelines in the Beverage Industry

Enhancing Beverage Industry Efficiency with Swisstech Schreiner's Expert Pipeline Construction. Discover how our innovative solutions streamline beverage production. Contact us for top-notch pipeline construction and optimization services.

Ưu điểm của máy hàn quỹ đạo (orbital welding machine) trong ngành công nghiệp hiện đại

Hiện nay, nhu cầu sửa chữa và bảo trì các thiết bị, máy móc trong các khu công nghiệp và nhà máy rất lớn. Máy hàn quỹ đạo (orbital welding machine) đã trở thành công cụ quan trọng trong việc bảo trì và sửa chữa các bộ phận máy móc, nhất là trong ngành công nghiệp. Trong bài viết này, hãy cùng Swisstech Schreiner tìm hiểu về ưu điểm khi sử dụng máy hàn quỹ đạo trong ngành công nghiệp hiện đại.

Sửa chữa mối hàn: Phân loại, quy trình và những lưu ý quan trọng

Sửa chữa mối hàn Maintenance work welding là một phần không thể thiếu trong các ngành công nghiệp liên quan đến sản xuất và bảo trì thiết bị. Bài viết dưới đây của Swisstech Schreiner sẽ cung cấp cái nhìn toàn diện về các loại sửa chữa mối hàn, phương pháp thực hiện và những lưu ý quan trọng trước khi tiến hành.

Kỹ thuật sử dụng máy hàn quỹ đạo Orbital welding machine cho mối hàn hoàn hảo

Máy hàn quỹ đạo Orbital welding machine là một trong những công nghệ hàn hiện đại và tiên tiến nhất hiện nay. Trong bài viết này, hãy cùng Swiss Tech Schreiner sẽ cùng tìm hiểu về kỹ thuật sử dụng máy hàn quỹ đạo Orbital welding machine cho mối hàn hoàn hảo.

Giảm thiểu nguy cơ khi dùng máy hàn orbital: Giải pháp an toàn cho thợ hàn

Khám phá các mối nguy hiểm phổ biến khi hàn quỹ đạo và cách giảm thiểu rủi ro hiệu quả. Cùng Swistech Schreiner Tìm hiểu ngay các biện pháp an toàn giúp bảo vệ sức khỏe và tối ưu hiệu suất làm việc!