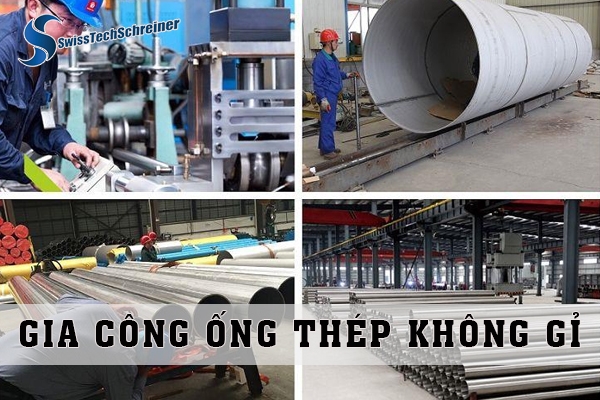

People often laud stainless steel for its strength, corrosion resistance, and aesthetic appeal. It has found extensive applications in modern infrastructure. Stainless steel has made its mark everywhere, from the exteriors of skyscrapers to the complex designs of the pipeline systems in industry. But a significant facet of this material's utility lies in its transformation into pipes. Let's have Swisstech Schreiner delve into the world of stainless steel pipe processing.

Detail of Stainless Steel Pipes Processing

The Birth of Stainless Steel Pipes

Before a stainless steel pipe graces our homes or industries, it starts as a raw coil or a plate. This raw material is molded into a round shape, either through welding or a seamless process.

Welded Pipes: Here, flat steel plates are shaped into tubes and then welded along the seams.

Seamless pipe raw material : These are crafted by heating a billet and then stretching it over a series of mandrels to give it a hollow shape.

Cutting and Sizing

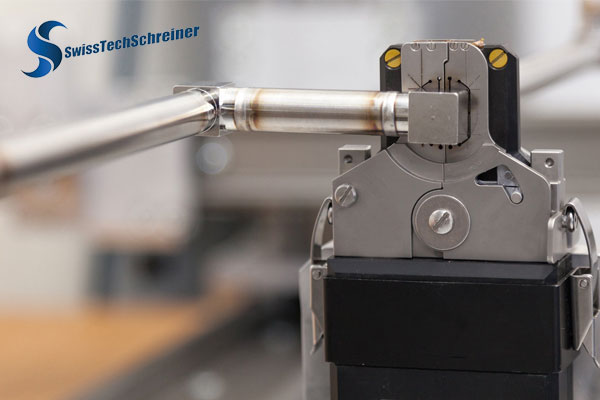

With the basic pipe structure in place, it's time for precision. Advanced cutting tools, such as laser cutters and plasma torches, come into play. They ensure the pipes are cut to desired lengths with finishes that are smooth, ensuring that each section fits perfectly in its destined application.

Heat Treatment and Conditioning

Heat plays a pivotal role in enhancing the properties of stainless steel. Through processes like annealing, where the pipe is heated and then cooled, the steel's microstructure is modified, enhancing its durability and workability.

Polishing and Finishing

A hallmark of stainless steel is its lustrous finish. Pipes undergo several rounds of polishing to achieve that signature shine. Whether it's a mirror finish or a brushed look, the finishing process ensures that the pipe isn't just functional but also aesthetically pleasing.

Testing and Quality Assurance

Before a stainless steel pipe finds its way into a building or machinery, it's rigorously tested. From checking the pipes for leaks to ensuring they can withstand pressure. They have to test to guarantee that the pipe will function optimally and safely.

The Environmental Footprint

Modern stainless steel pipe processing is also about responsibility. Many current advanced facilities focus on sustainable practices, ensuring minimal waste and recycling excess material.The reason is that it's not just about creating a durable product, but doing so in an environmentally-conscious manner.

Stainless steel pipe processing is a meticulous journey from a raw, sturdy alloy to a polished, resilient tube. These pipes were born with precision and care. They serve an important role in our daily lives and modern industries. The next time you glimpse a shiny steel surface or turn on a tap, remember the impressive engineering and artistry behind that simple pipe.

=> Read more about Stainless Steel Pipe Processing :

=> Quy trình gia công ống thép không gỉ (Stainless steel pipe processing) cụ thể và chi tiết

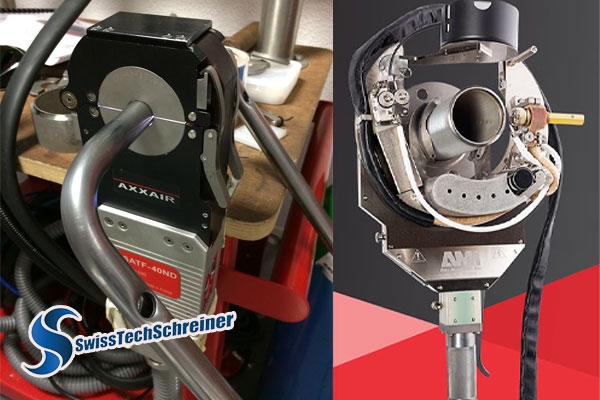

Swisstech Schreiner: Mastering Orbital Welding for Stainless Steel Pipes

In the complex world of stainless steel pipe processing, precision is paramount. Let's go with Swisstech Schreiner, a company of innovation that champions the advanced application of orbital welding technology. With a commitment to excellence, Swisstech Schreiner seamlessly blends tradition with technology, offering top-tier services in stainless steel pipe processing by orbital welding technology.

Swisstech Schreiner Pioneers in Precision

Swisstech Schreiner isn't just another name in the industry; it's a hallmark of quality. Their embrace of orbital welding technology for stainless steel pipes showcases their dedication to providing cutting-edge solutions, ensuring precision, consistency, and integrity in every project.

The Orbital Welding Technology Advantage

Harnessing the power of orbital welding, Swisstech Schreiner guarantees:

- Uniformity: Achieving consistent, 360° welds around pipes, ensuring structural integrity.

- Efficiency: Drastically reducing the processing time compared to conventional methods.

- Purity: Delivering contamination-free welds, essential for industries like pharmaceuticals industry , semiconductors, and food & beverage industry.

- Custom Solutions: Tailoring the welding parameters to suit the specific requirements of each project.

Industries Served

Swisstech Schreiner's expertise extends across multiple sectors:

- Pharmaceuticals industry: Prioritizing ultra-clean welds for contamination-free operations.

- Semiconductors: Ensuring ultra-high purity in systems.

- Chemical and biography: Delivering precision welds to meet rigorous standards.

- Food and Beverage industry: Offering hygienic solutions with impeccable weld finishes.

Quality Assurance: Beyond the Weld

The team at Swisstech Schreiner doesn't just stop at welding. Every processed pipe undergoes stringent quality checks to ensure that clients receive nothing but the best.

Sustainable & Future-Ready

In line with global trends, Swisstech Schreiner emphasizes sustainable practices. By optimizing resource usage and minimizing waste, Swisstech Schreiner not only delivers exceptional services but also does so responsibly in the orbital welding, construction of pipeline systems, maintenance work,...

=> See the detail about stainless steel pipe processing by orbital wwelding technology at :

Swisstech Schreiner, with its expertise in orbital welding technology, has positioned itself as a current leader in stainless steel pipe processing in Vietnam. By prioritizing precision, innovation, and customer satisfaction, they offer services that are not just technologically advanced but also logically sound. For businesses seeking the perfect blend of tradition, technology, and trust, Swisstech Schreiner is the name to rely on.

Stay updated on industry innovations and breakthroughs. Connect with us for more insights into the world of advanced manufacturing and beyond

Swisstech Schreiner.

Add: ch 4153 reinach and hcm city vietnam

Hotline: (+84) 931 - 386 - 062

Phone: (+84) 931 - 386 - 062 +84931386062 ( zalo / viber / whatsapp )

Email: swiss.tech.schreiner@gmail.com

Other News

Gia Công Ống Thép Không Gỉ: Giải Pháp Tối Ưu Cho Nhiều Ngành Công Nghiệp

Cùng Swisstech Schreiner khám phá các phương pháp hàn thép không gỉ và tiêu chí lựa chọn phù hợp cho dự án của bạn trong gia công ống thép không gỉ stainless steel pipe processing. Tìm hiểu sự đa dạng của các kỹ thuật hàn để đảm bảo chất lượng sản phẩm và hiệu quả sản xuất.

Tầm Quan Trọng Của Việc Bảo Trì Máy Hàn Maintenance work welding

Khám phá lịch trình bảo trì định kỳ cho máy hàn Maintenance work welding để đảm bảo hiệu suất tối ưu và an toàn cao nhất. Từ bảo trì hàng giờ đến hàng năm, hãy tìm hiểu cách giữ cho thiết bị của bạn hoạt động mượt mà. Liên hệ Swisstech Schreiner để biết thêm chi tiết và hỗ trợ

Các kỹ thuật hàn quỹ đạo trong ống dẫn dược phẩm

Các kỹ thuật hàn quỹ đạo - Orbital welding technology cung cấp giải pháp lý tưởng cho các thách thức về vệ sinh và kín khí trong môi trường sản xuất dược phẩm. Bài viết này của Swisstech Schreiner sẽ khám phá chi tiết về các kỹ thuật hàn quỹ đạo phổ biến.

Kiểm soát chất lượng và an toàn khi sử dụng hàn quỹ đạo

Bài viết này của Swisstech Schreiner nhằm mục đích cung cấp một cái nhìn sâu sắc về các nguyên tắc và phương pháp tốt nhất để đảm bảo kiểm soát chất lượng và an toàn tối ưu khi sử dụng máy hàn quỹ đạo Orbital welding machine.

Orbital welding technology applied to industrial pipeline construction

With its unmatched accuracy and consistency, this cutting-edge tool has become indispensable for projects demanding the utmost quality. Let's learn about orbital welding technology with Swisstech Schreiner through the following article

Steps for stainless steel pipe processing

Before embarking on the stainless steel pipe processing, it is crucial to undertake a series of preparatory steps to ensure the success and safety of the welding operation. Join Swisstech Schreiner to learn about the steps taken in the process of welding and processing industrial steel pipes effectively.