What is an orbital welding machine? Learn about orbital welding machines and operating principles, along with the services Swisstech Schreiner provides to customers on construction and installation of pipeline systems in the pharmaceutical, beverage industry , chemical, biotechnology industry .. .by automatic orbital welding technology.

WHAT IS ORBITAL WELDING MACHINE?

The perfect weld is represented by an orbital welding machine in an evolving automation system.Swisstech Schreiner offers one-of-a-kind and efficient solutions for tube and pipe welding in the manufacturing industry, as well as new solutions for integrating cutting-edge technologies such as orbital welding machines.

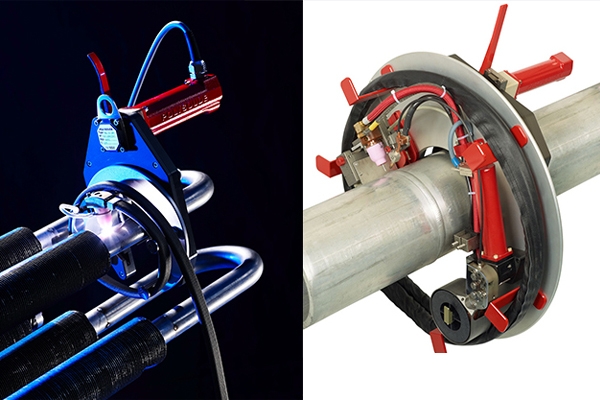

For fusion (GTAW) welding of fittings, tubing, and thin wall pipe, factories used orbital welding machines with orbital weld heads. The ideal welding solution for the pharmaceutical, biotechnology, chemical, food and dairy, beverage, and semiconductor industries.

Also, it is used whenever there is a severe lack of workspace. Also, it excels at welding all typical micro fittings. fuses materials like titanium, alloy, and other auto-weldable alloys to stainless steel pipe manufacturing. Argon protection and tungsten insert (TIG) welding are used during the welding process instead of wire feeding.

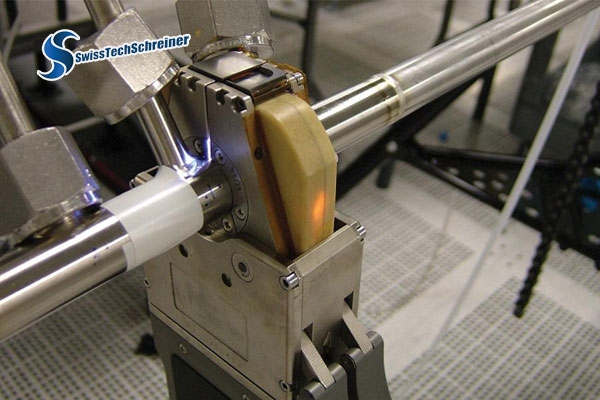

In the manual welding method, it is difficult for the welder to create welds with high uniformity when the number of welds is too large. Therefore, orbital welding technology was born to overcome the errors that welders may cause during manual pipe welding such as burnt welds, uneven welds, ....

Welding with an orbital welding machine does not require direct welder involvement in the welding process. Orbital welders can produce thousands of uniform welds by repeating the welding process according to a pre-programmed process.

STRUCTURE OF ORBITAL WELDING MACHINE

The orbital welding machine is composed of a power control unit, a welding head, a water-cooled unit, and a compensating welding wire feed mechanism (depending on the case). In which, arc length, repetition frequency of pulses in the welding current, flue gas and argon gas are factors that can affect the welding results. In order to have high-quality welds, the mechanic needs in-depth knowledge to adjust the correct usage parameters. Swiss will support customers from supplying the machine to showing them how to use it to achieve the best weld quality.

WHERE DOES IT FIT IN

Orbital welding machines have been utilized to produce piping for a variety of sectors as well as clean-room components for the semiconductor industry since they can produce high-purity welds. The automotive, aerospace, biotechnology, chemical engineering, food and beverage industry, pharmaceutical, power, and shipbuilding industries are just a few that use orbital welding technology.

REQUIREMENTS IN ORBITAL WELDING TECHNOLOGY PROCESS

Welding amperage needs to be continuously controlled to result in uniform welds. Pipe thicknesses that can be used with orbital welders are over 0.5 mm and up to 4mm. Shielding gas flow can be controlled to provide sufficient shielding gas and equalize pressure inside and outside the tube. The oxygen concentration of the shielding gas stream must be at least 50 parts per million.

During pipe welding, the pipes must be concentric and of the same size. because if the external pressure is higher, it will cause the weld to be concave in or vice versa, making the pipe convex. Control the temperature of the welding part to minimize the possibility of the weld being burned, oxidized, or denatured. material. Limit the discoloration of welded parts, especially when processing stainless steel pipes.

=>> Read more : Various orbital welding machine applications

Even with unusual materials, pieces with a significant wall thickness, small diameters, or hazardous conditions, orbital welding machines can produce reliable welds with high consistency. Thanks to the above factors, the application of orbital welding machines in industries and other fields is increasingly widespread.

While the cost of the necessary equipment is somewhat high (5–10 times as much as conventional equipment), orbital welding machine can provide 2-3 times higher productivity than traditional TIG welding.

Add: ch 4153 reinach and hcm city vietnam

Hotline: (+84) 931 - 386 - 062

Phone: (+84) 931 - 386 - 062 +84931386062 ( zalo / viber / whatsapp )

Email: swiss.tech.schreiner@gmail.com

Other News

Tối Ưu Quy Trình Hàn Ống Với Máy Hàn Quỹ Đạo Tự Động - Orbital welding machine

Máy hàn quỹ đạo (Orbital Welding Machine) được xem là công nghệ tiên tiến hàng đầu, giúp tối ưu hóa hiệu suất và chất lượng sản xuất. Nhờ khả năng tự động hóa cao, chất lượng mối hàn ổn định và tốc độ thi công nhanh chóng, thiết bị này đang ngày càng được ứng dụng rộng rãi trong các lĩnh vực.

Cấu tạo của máy hàn quỹ đạo (orbital welding machine) và cách hoạt động

Máy hàn quỹ đạo (orbital welding machine) là gì? Cấu tạo và cách thức hoạt động của máy là như thể nào? Hãy cùng Swisstech Schreiner tìm hiểu chi tiết về máy hàn quỹ đạo (orbital welding machine) ở bài viết dưới đây nhé.

Giới thiệu công nghệ hàn quỹ đạo - Orbital welding technology

Công nghệ hàn quỹ đạo (orbital welding technology) ngày càng phổ biến vì nhiều công ty thực phẩm, đồ uống và dược phẩm. Hãy cùng Swisstech Schreiner tìm hiểu kỹ hơn về công nghệ này qua bài viết sau.

SwissTech Cung cấp hàn quỹ đạo ngành nước giải khát (Beverage Industry)

Nếu doanh nghiệp của bạn đang tìm kiếm một đơn vị cung cấp thiết bị máy hàn orbital cũng như các giải pháp thi công, lắp đặt đường ống chất lượng cao, hãy liên hệ với SwissTech. Chúng tôi cam kết mang lại giải pháp tối ưu nhất, đáp ứng mọi yêu cầu khắt khe của khách hàng trong các ngành công nghiệp quan trọng.

Swisstech Schreiner provides the solution for Stainless Steel Pipe Processing With Orbital Welding technology

Join Swisstech Schreiner in embracing a new era of stainless steel pipe processing, where technology meets ingenuity. Swisstech Schreiner's dedication to innovation continues to reshape possibilities and elevate industry standards. Experience the future of welding – precise, efficient, and flawlessly connected.

Quy Trình Bảo Trì Hàn Quỹ Đạo-Maintenance work welding

Quy trình bảo trì hàn quỹ đạo không chỉ đơn thuần là làm sạch hay thay thế linh kiện. Đó là một chiến lược toàn diện nhằm bảo đảm hệ thống luôn hoạt động chính xác, hiệu quả, an toàn và giúp doanh nghiệp gia tăng năng suất và tối ưu hóa lợi nhuận