On the market, there are numerous welding technologies. The latest technology employed in industries where there is a need for weld quality, efficiency, productivity, and simplicity improvement is orbital welding technology. This article by Swisstech Schreiner gives an overview of the technology, taking into account all of the aforementioned variables.

Overview of orbital welding technology

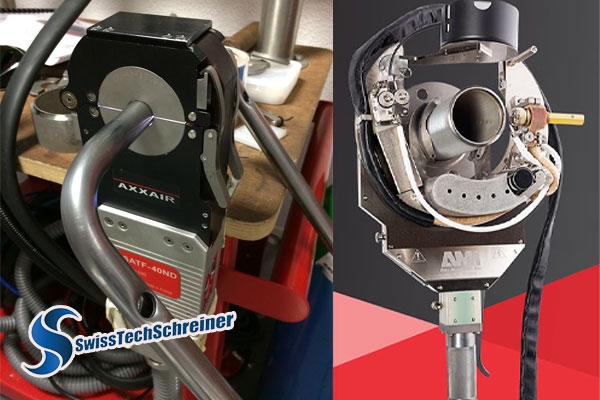

The method used to join the pipes or tubes followed a certain trajectory and is known as orbital welding technology. This technology is widely applied in the case of pipelines on a large scale, where a number of pipes are joined together.

There is a chance that the joints on these pipelines could leak. If the pipelines are utilized for the supply of gas or any other hazardous liquids, such as acid, etc., these leakages could be dangerous.

The leakage could also result in a drop in output, which would affect the hygiene situation. It is necessary for welding technology to advance in order to solve these issues. Because pipeline utilization is expanding daily, orbital welding is becoming more and more necessary.

Tube welding is currently becoming just as important to the sector as pipe welding. These tubes or pipes are mass produced in various sectors, so those industries require an increase in productivity. So, an advancement in orbital welding technology is needed for that.

Application of Orbital Welding technology

The use of orbital welding technology is increasing in a variety of industries. Currently, their applications are growing every day. The following is a list of some of their applications.

Aerospace

The benefits of automated orbital welding were initially understood by the aerospace sector. A single aircraft's high-pressure systems can have more than 1,500 automatically produced welded joints made by orbital welding machines.

Dairy, food, and beverage industry

For all weld joints in these industries, full penetration welds must be consistent. The tube and tubing welds need to be as smooth as possible for the pipe system to operate at its best efficiency. Every pit, fissure, crack, or imperfect weld joint might catch the liquid circulating inside the tube, creating a breeding ground for germs.

Industry of pharmaceuticals

Water of the highest caliber is supplied to pharmaceutical processes through piping systems and process lines. To guarantee that the water coming from the tubes is free of germs, rust, or other impurities, high-quality welds are necessary. Using orbital welding, full-penetration welds are guaranteed without overheating, which can reduce the final weld zone's ability to resist corrosion.

Industry of semiconductors

To avoid contaminant buildup on the tube wall or weld joints, the semiconductor sector demands pipe systems with exceedingly smooth interior surface finishes. A buildup of contaminants, moisture, or particulates could release once it becomes large enough and damage the batch process.

Valves, regulators, and pipe and tube fittings

Tubing with termination fittings is necessary for medical systems, liquid and gas distribution systems, and hydraulic lines. Optimal weld quality and excellent welding productivity are made possible by orbital systems.

These days, there is more competition in the producing industries. Customers seek high-grade products that are of good or excellent quality. There are no longer any chances for defects in the product. A change in manufacturing is required to survive in this cutthroat world.

Weld quality is increased, weld speed is increased, and scrap and rework costs are decreased when the welding process is optimized. The companies can obtain a lower cost per product with good quality and a short time by attaining these aims. It is simple to control the usage of the electrode, input material, shield can, etc. by using orbital welding technology and computer programming.

=>> Read more : Orbital welding technology ‘s definition and history

Swisstech Schreiner offers customers the solutions for the orbital welding technology, the pipelines in industries construction, maintenance work, etc., in a professional and meticulous way. Contact us for more information.

Swisstech Schreiner.

Add: ch 4153 reinach and hcm city vietnam

Hotline: (+84) 931 - 386 - 062

Phone: (+84) 931 - 386 - 062 +84931386062 ( zalo / viber / whatsapp )

Email: swiss.tech.schreiner@gmail.com

Other News

SwissTech Cung cấp hàn quỹ đạo ngành nước giải khát (Beverage Industry)

Nếu doanh nghiệp của bạn đang tìm kiếm một đơn vị cung cấp thiết bị máy hàn orbital cũng như các giải pháp thi công, lắp đặt đường ống chất lượng cao, hãy liên hệ với SwissTech. Chúng tôi cam kết mang lại giải pháp tối ưu nhất, đáp ứng mọi yêu cầu khắt khe của khách hàng trong các ngành công nghiệp quan trọng.

Precision and Durability Stainless Steel Pipe Processing

People often laud stainless steel for its strength, corrosion resistance, and aesthetic appeal. A significant facet of this material's utility lies in its transformation into pipes. Let's have Swisstech Schreiner delve into the world of stainless steel pipe processing.

Hệ Thống Đường Ống Chuẩn Quốc Tế Cho Bia Và Rượu - Beverage industry

Việc xây dựng hệ thống đường ống và dây chuyền sản xuất hiện đại, đạt tiêu chuẩn cao là một phần không thể thiếu trong chiến lược phát triển bền vững của các doanh nghiệp trong ngành nước giải khát và bia – rượu. Nhờ ứng dụng công nghệ hiện đại và sự đồng hành của đội ngũ kỹ sư giàu kinh nghiệm

Orbital welding technology applied to industrial pipeline construction

With its unmatched accuracy and consistency, this cutting-edge tool has become indispensable for projects demanding the utmost quality. Let's learn about orbital welding technology with Swisstech Schreiner through the following article

Orbital Welding Technology for Pipeline Systems Construction

As pharmaceutical companies strive for excellence in their operations, Swisstech Schreiner with Advanced orbital welding technology iss proving to be indispensable tools, ensuring the continued production of safe and high-quality medications for the world.

Công nghệ hàn quỹ đạo đảm bảo an toàn thực phẩm

Hãy cùng Swisstech Schreiner tìm hiểu về cách thức vận hành công nghệ hàn quỹ đạo (orbital welding technology) giúp tăng cường hiệu suất sản xuất mà còn đảm bảo chất lượng bề mặt liên kết, giảm thiểu nguy cơ ô nhiễm trong quá trình sản xuất thực phẩm trong các nhà máy thực phẩm qua bài viết sau.