Orbitale Rohrsägen

DC65-MS

orbital facing machine: light and easy to transport, can be used on the construction site and in the workshop.

facing pipes consists of achieving a perfect degree of conformity of the pipe end.

this conformity concerns three aspects: the squareness - the burr-free surface of the pipe and possibly a length adjustment of the pipe.

burr-free planning without scratching the pipe, the pipe chip is rolled outwards.

ideal preparation before orbital welding of thin-walled pipes.

Tensioning crank with indexable pin and spring system

High quality HSS- E TIALN indexable inserts

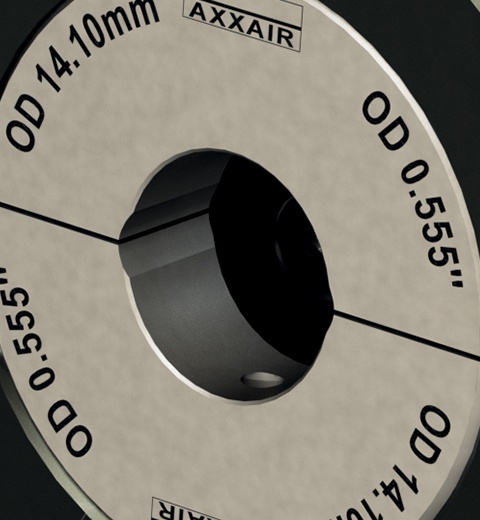

Profiled clamping jaws made of stainless steel

Supplied in a waterproof and dustproof anti-shock case

Pipe planing machine for burr-free planning after a band saw cut or for electropolished pipes

- Ideal tool for planing before automatic welding

- New brushless motor, 18V

- 220-240 V ~ 50 / 60Hz or 100-120 V ~ 60Hz

- Precise manual feed, graduated vernier

- Light and compact (5.5 kg)

- two-stage reduction gear with wheel for speed control

- stainless steel clamping jaws with large opening and spring system

- Ideal tool for planing before automatic welding

- New brushless motor, 18V

- 220-240 V ~ 50 / 60Hz or 100-120 V ~ 60Hz

- Precise manual feed, graduated vernier

- Light and compact (5.5 kg)

- two-stage reduction gear with wheel for speed control

- stainless steel clamping jaws with large opening and spring system