DC221-AMx

orbital facing machine, can be used on the construction site as well as in the workshop.

facing pipes consists of achieving a perfect degree of conformity of the pipe end. this conformity concerns three aspects: the squareness - the burr-free surface of the pipe and possibly a length adjustment of the pipe.

burr-free planning without scratching the pipe, the pipe chip is rolled outwards.

ideal preparation before orbital welding of thin-walled pipes.

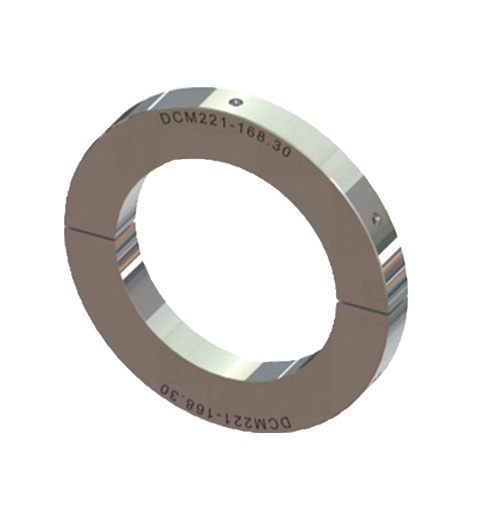

Stainless steel clamping jaws

Easy and precise clamping of the pipe

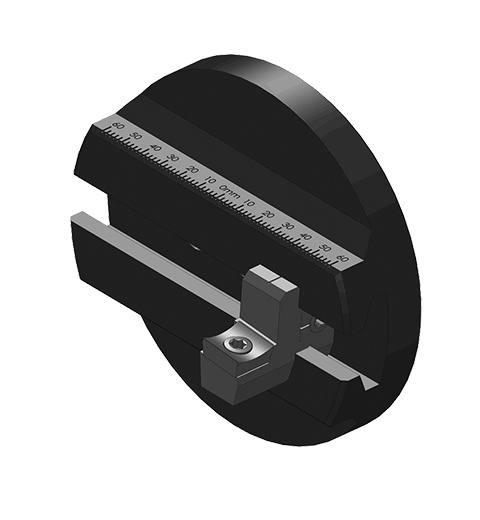

Simultaneous use of two tools possible

Delivered in a protective case

- Planer for pipes and broken webs used after cutting with a band saw or on electropolished pipes

- Wall thickness: <3mm (depending on the material)

- Ideal for planning before automated welding

- Precise manual feed: 0.1 mm tolerance

- Adjustment of the tool support through Shifting: this enables an easy setting according to the diameter and an optimization of the tool wear

- 30 ° and 40 ° degree outer

bevel possible with the tool support option - Plane and bevel in one operation - Possibility to use three tools at the same time

- Minimum tube length: 39 mm

- In one Producttective box supplied

- Light and compact: 21 kg

- 1100W motor

- 2 speeds: wide range of speeds

- wheel and screw drive to optimize the speed range and avoid vibrations