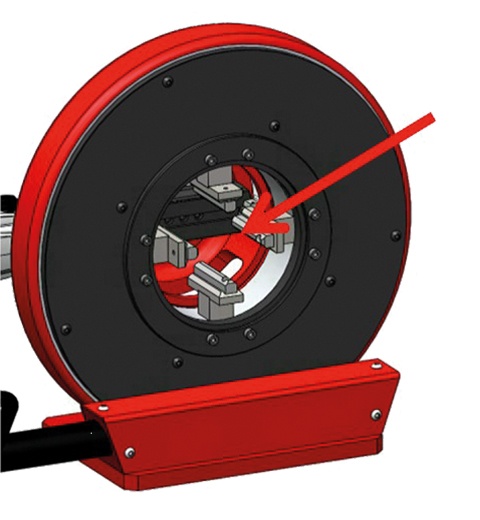

DC115-BMx

orbital facing machine, can be used on the construction site as well as in the workshop.

facing pipes consists of achieving a perfect degree of conformity of the pipe end. this conformity concerns three aspects: the squareness - the burr-free surface of the pipe and possibly a length adjustment of the pipe.

burr-free planning without scratching the pipe, the pipe chip is rolled outwards.

ideal preparation before orbital welding of thin-walled pipes.

Concentric clamping system

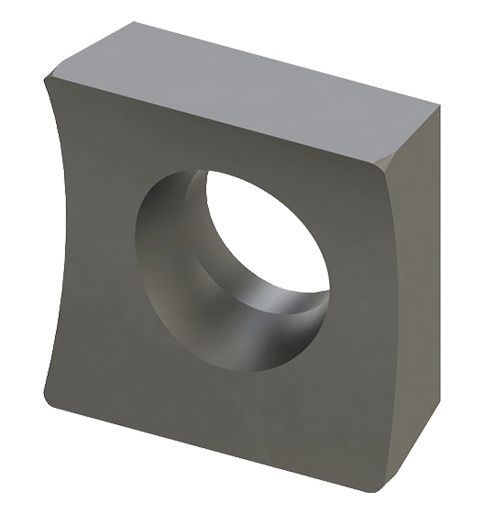

High quality HSS- E TIALN indexable inserts

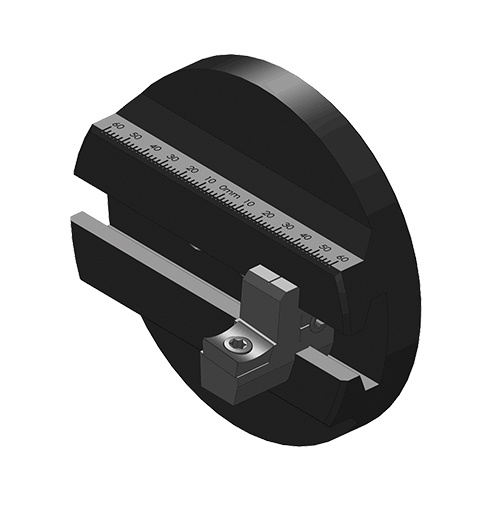

The sliding fit of the tool holder makes it easy to change the diameter

Option: assembly on the pipe support bench

- Large diameter range: Ø12 to Ø115 mm thanks to concentric clamping in the entire diameter range Burr-free planing and beveling machine

- Thickness <3 mm (depending on the material)

- The ideal tool for planing a band saw cut before automatic welding

- Precise manual feed: 0.1 mm scale 0.004 inch

- The sliding fit of the tool holder ensures a simple change of diameter and optimal cutting plate wear

- 30 ° and 45 ° outer bevel possible with optional tool holder - Planing and chamfering in one work step

- Simultaneous use of both tools possible

- Minimum straight length of the tube: 58 mm

- Delivered in a wooden box

- Weight: 37 kg / 82 lbs

- 1100W motor with wide speed range (2 gears) worm gear for optimal speed range